In the current competitive world of manufacturing and packaging, selecting the right filling machine in your business is more than a technical decision it is a strategic one. It doesn’t matter whether you manufacture drinks, cosmetics, perfumes, pharmaceuticals or chemicals, the appropriate machine determines your production efficiency, quality of the products, as well as profitability.

This is the ultimate guide that discusses all aspects of choosing the best filling machine between types of machines and main characteristics to industry-specific demands. You will also see how specialized solutions such as bottle filling machines, liquid filling machines and water filling machines can improve your production line.

What Is a Filling Machine?

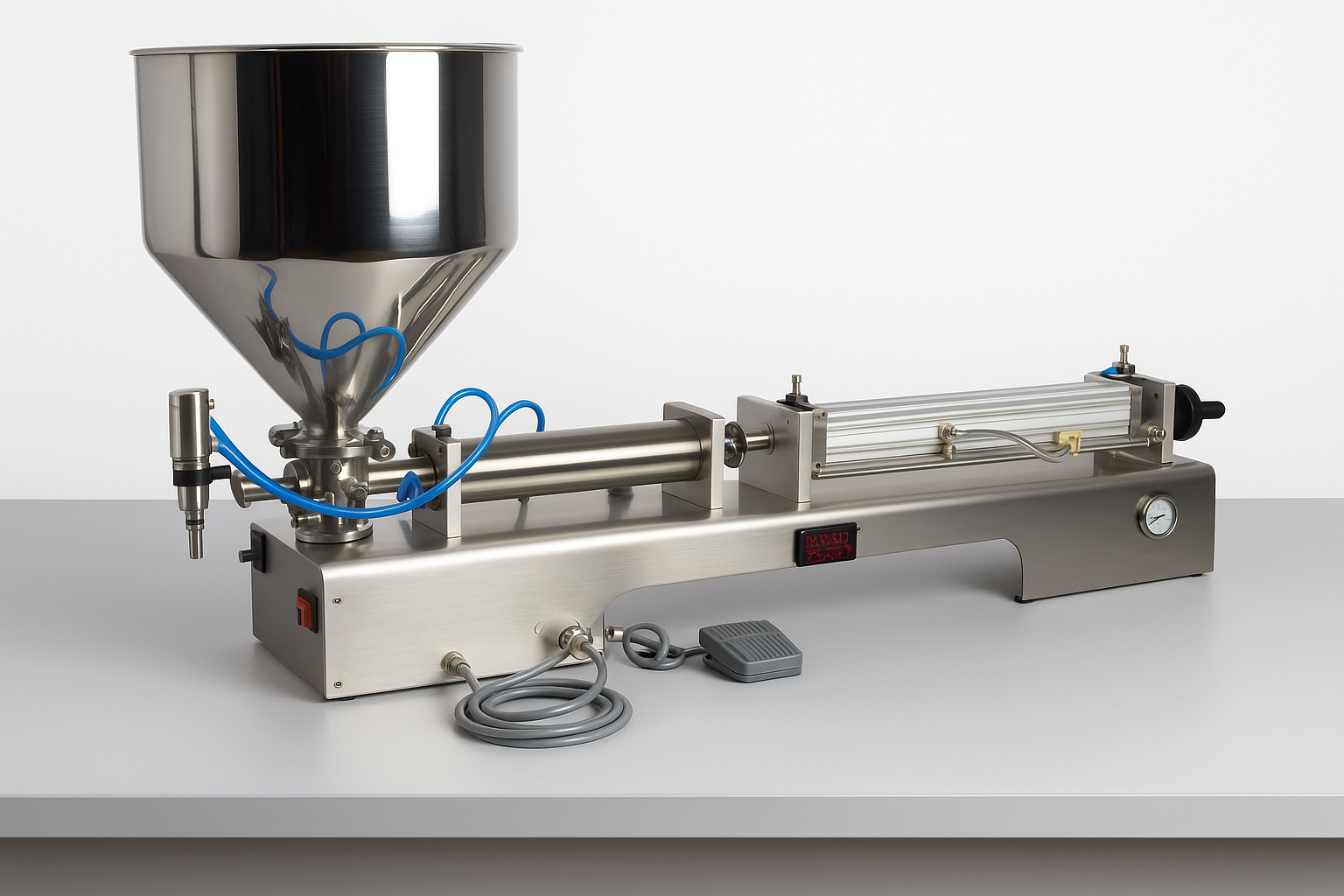

A filling machine is a machine that is used to fill containers with a specific volume of liquid or thick material automatically. It’s the backbone of most packaging lines, ensuring accuracy, hygiene and consistency across every unit produced.

The machines are common in the food and beverage, pharmaceutical, cosmetic, perfumery and chemical industries. A filling machine can be adapted to various container types such as bottles, jars, pouches or tubes depending on the texture of the product and the packaging type, and is therefore versatile and cannot be done without in the modern manufacturing industry.

Why Choosing the Right Filling Machine Matters

The right filling machine will have an effect on all your production processes. It identifies the speed, neatness and precision under which you are able to pack your product in quality and efficiency.

A high precision machine helps in creating the right amount of each bottle or jar ensuring that there is no wastage of the products, and it improves brand consistency to an extent. Through automated systems, the throughput is significantly enhanced with thousands of containers being filled in one hour. Hygienic designs prevent the contamination of food, cosmetics, and pharmaceuticals. And a scalable machine can easily respond to changes in production or product range.

Types of Filling Machines

Filling machines come in different automation level and mechanism options that provide the business with a range of choices that best fit its process.

Manual machines are best suited when starting up or with small batches. Semi-automatic machines are more precise and fast and cost-efficient. Complete automatic systems are used with bottle feeding, filling, capping, and labeling with minimum human intervention – a requirement where high volumes are involved.

There are various filling mechanisms that serve various types of products. Gravity fillers are appropriate when dealing with liquids of low density such as water, whereas piston fillers are used when dealing with the viscous fillers like creams or sauces. Overflow, vacuum, and counter-pressure machines correspond to carbonated drinks, sensitive perfumes or wines, and ensure the same level of visuals respectively.

5 Important Things to Consider When Selecting a Filling Machine

The choice of the appropriate filling machine depends on your product features, type of container, volume of production and the surroundings.

Viscosity

The viscosity is used to determine the ease of flow of your product. Whereas thinner fillers such as syrups are acceptable, thicker fillers like gels demand the use of piston or pump fillers. The and slim products like water or alcohol are more effective with either the vacuum or gravity systems. Volumetric systems are ideal in accurate measured fills in all viscosities.

Production Environment

Your working environment defines what machine to use.. The manual fillers may be used in almost any place whereas the semi-automatic and fully automatic must have steady power and compressed air. The use of stainless-steel construction and clean-in-place (CIP) technology is needed in industries that have stringent measures against hygiene.

Container Type

Containers influence filling behaviour. Gravity or vacuum fillers work well with glass and rigid plastic bottles, but volumetric systems should be used with flexible containers, pouches or large drums to counter the flexibility. The very large containers (greater than 5 L) have detachable nozzles that enable the operators to fill them at ground level in a safe way.

Production Scale

Small- batches can be dependent on manual or semi-automatic machines that are easy to wash and change in the product. Automatic systems consisting of multiple nozzles, conveyors and rotary arrangements are useful in large-scale manufacturers and significantly raise the output without affecting the accuracy.

Filling Accuracy

Quality control and cost management are dependent on precision. Vacuum level systems guarantee even heights of visible fill – ideal in glass bottle retail shelves. Volumetric fillers provide precise volumes, and are perfect with pharmaceuticals and high-end cosmetics.

Industry-Specific Filling Machines

Each industry has its unique filling needs and manufacturers come up with filling machines that meet that specific needs accurately. The four main areas that are most dependent on these machines are listed below.

Food and Beverage Industry

Here, speed, hygiene and flexibility are the priority. The machines should deal with various products and include thin juices up to thick sauces and maintain cleanliness. Stainless steel designs simplify sanitation and adjustable systems accommodate bottles, jars and pouches. A brand of beverage can use the high-speed bottle filling machine to fill the bottles of juice with thousands of bottles per hour without spillage and inconsistency.

Pharmaceutical Industry

Pharmaceutical packaging is characterized by precision and sterility. Containers should contain the correct dosage and any contamination is not permissible. This industry is constructed of machines that are designed in aseptic conditions and meet the standards of FDA and GMP. A pharmaceutical filling machine guarantees one the optimal dosing and sterile functioning safeguarding the product and patient safety.

Perfume Industry and Cosmetic Industry.

Fragrance and cosmetic items require precision and beauty. These come in different shapes and sizes, as some are in thin perfumes or thick lotions and hence, it is important to be flexible. Light filling helps to avoid foaming or bubbles and yield smooth and pleasing looks. Vacuum fillers have become very popular in the manufacture of perfumes due to their clean and accurate functioning as well as their capacity to maintain the quality of the smell.

Chemical Industry

The chemical industry needs to be tough and safe. The machines should be able to treat corrosive or reactive liquids such as acids, cleaners or solvents without leakages or any damages. The chemical filling machines are designed with safety valves and corrosion-resistant materials to guard against the operators and ensure efficient and clean working.

Special Focus: Water Filling Machines

A water filling machine is designed in a way that is hygienic, consistent, and fast. These systems have a system that rinses, fills, and caps in a single automated cycle. They are capable of filling between 2,000 and 20,000 bottles in an hour and both PET and glass bottles. Sparkling water is packed in a counter-pressure model in order to keep it carbonated and fresh. These machines are a one solution package to beverage producers.

Key Features of a Modern Filling Machine

The filling machines in the modern age have user-friendly touch screens on the PLC, servo-operated nozzles, and they are designed in such a way that they can easily be upgraded. They are designed for quick changeovers between bottle sizes, minimal energy use and effortless cleaning. Smart sensors can track the performance and automatically make adjustments, minimizing wastage and enhancing accuracy.

Maintenance and Troubleshooting

Routine care ensures smooth, long-term performance. Clean the nozzles after each batch, lubricate moving components, and check seals regularly. Calibrate sensors periodically to maintain accuracy. Well-trained operators can resolve small issues quickly and prevent downtime. Preventive maintenance keeps production continuous and reliable.

Common Mistakes to Avoid

Many companies overlook important factors when purchasing a filling machine. Disregard of the product viscosity, hygiene needs, or after-sales services may lead to inefficiencies in the future in serious ways. Making decisions based on the lowest cost without taking into account the long-term costs usually results in the failure to operate on a regular basis. These traps can be avoided by planning for scalability and effective maintenance right at the beginning.

Future Trends in Filling Machine Technology

The future generation of filling machines is aimed at being smart, sustainable, and adaptable. Fill levels are now mastered by artificial intelligence. Robotics enhances speed and accuracy and also saves on labor. Green systems use less energy and utilize materials that are recyclable. IoT connectivity allows remote access and maintenance prediction as well as performance tracking to guarantee maximum uptime and efficiency.

Final Checklist Before You Buy

Always ensure that your filling and packaging machine fits all your precise production requirements before you make final investment. A decision made today will determine your business efficiency over the years. Here’s your quick checklist:

Check Product Compatibility

Make sure the machine is compatible with your product, i.e., will it be honey, oil, perfume, or sanitizer. Akikai packaging machines are designed with high precision that can fill a variety of viscosities with precision and smooth filling every time.

Verify Container Compatibility

From glass to plastic, jars to bottles, Akikai machines adapt easily to different container materials and sizes, saving you setup time and wastage.

Evaluate Your Production Target

Select a business scaled model. The Akikai manual, semi-automatic, and automatic machines are programmed to meet the requirements of startups and established manufacturers, thus you grow without growing beyond your machine.

Accuracy & Hygiene

All Akikai packaging equipment is designed to fill accurately and not be contaminated at all, based on high hygienic requirements that maintain the quality of your product.

Dependable After-Sales Support

Akikai, from the house of Ajanta Bottle, comes with reliable service, quick parts availability, and expert guidance, ensuring your investment keeps performing for years.

Ajanta Bottle: 44 Years of Packaging That Builds India’s Shelf Presence

With over 44 years of legacy in the Indian packaging industry, Ajanta Bottle has become more than just a packaging supplier—it is a trusted partner to brands looking to scale, differentiate, and lead through design.

From the early days of supplying classic glass containers for pharmaceuticals and household staples to now providing premium glass jars, lightweight bottles, and customized aluminum cans for food and beverage businesses, Ajanta has stayed ahead by understanding what packaging really means in a competitive market.

We have worked with countless Indian brands, both legacy and new-age, helping them:

-

Launch shelf-ready products with strong first-impression value

-

Shift from plastic to glass to enhance sustainability and consumer trust

-

Integrate packaging design with brand stories for premium perception

-

Optimize for retail stocking, e-commerce delivery, and food service convenience

Our in-house decoration unit, innovative packaging machinery under Akikai, and continuous investment in research and customer education (through platforms like PackSchool) make us uniquely placed to support packaging transformations that matter.

Whether it’s a cold-pressed juice in a sleek amber glass bottle or a handcrafted pickle in a heritage-inspired jar, Ajanta Bottle enables food and beverage brands to lead with packaging that speaks louder than words.

We don’t just supply containers.

We build packaging stories that sell.

Ready to create the perfect glass packaging for your brand?

Connect with us:

● Email at sales@ajantabottle.com

● Phone/Whatsapp: +91 9891098918

You can also shop from more than 500+ packaging solutions on www.ajantabottle.com – India’s first ever comprehensive packaging e-commerce portal.

For additional information, browse through our blog at https://www.ajantabottle.com/blog/ or subscribe to our latest updates through our social media channels,

*YouTube channel: https://www.youtube.com/c/Ajantabottle

*LinkedIn Page: https://www.linkedin.com/company/ajantabottle

*Facebook Page: https://www.facebook.com/glassbottleindia

*Instagram Page: https://www.instagram.com/ajantabottle

*Google Business Profile Manager: https://g.page/r/CXTH9MKpe2DuEBM/review