In the current competitive packaging environment, each detail counts including the appearance of a bottle and the accuracy of its seal. An effective bottle cap sealing machine will make sure that not only does your product look professional but that it is safe, tamper-proof and durable. It is either you are packaging beverages, pharmaceuticals, cosmetics, or chemicals, the correct sealing solution can make the difference between a successful brand and not.

This blog covers all the information you need to know regarding bottle cap sealing machines, their types, use, main features, and how to select the appropriate purchase for your business.

What Is A Bottle Cap Sealing Machine

The bottle cap sealing machine is a specialized machine that is used in closing and sealing bottles in a secure manner that ensures the integrity of the products stored and transported. The principal objective is to attain an airtight, leakless and tamper evidenced closure.

Since bottles capping process involves twist screw capping and induction cap sealing machine which involve welding aluminum foils onto the mouths of the containers, these processes ensure uniform quality and efficiency.

They are indispensable across industries such as:

Food and Beverage: For juices, sauces, carbonated drinks and water.

Pharmacueticals: To preserve the sterility of tonics and medicines.

Cosmetics: For perfumes, serums, oils and creams

Chemical and Industrial Packaging: To clean the chemicals and solvents.

Why the Right Cap Sealing Machine Matters

There are no compromises in packaging in terms of consistency and safety. The failure to provide a strong or non-uniform seal may lead to leakages, contamination or spoilage all of which may hurt customer confidence.

A high-quality cap sealing machine will guarantee:

- Zero leakage and contamination

- Enhanced shelf life

- Compliance with international packaging standards

- Professional presentation on retail shelves

Different Types of Bottle Cap Sealing Machines

New packaging systems incorporate the deployment of various machines depending on the volume of production, the type of bottles, and the form of bottle closure. This is a brief description of the principal types:

Automatic Bottle Cap Sealing Machine

1. Full automated systems which are attached to conveyor-based bottling lines.

2. Best suited for high-speed production processes such as massive beverage or pharmaceutical facilities.

3. Torque and accuracy at all seals must be the same.

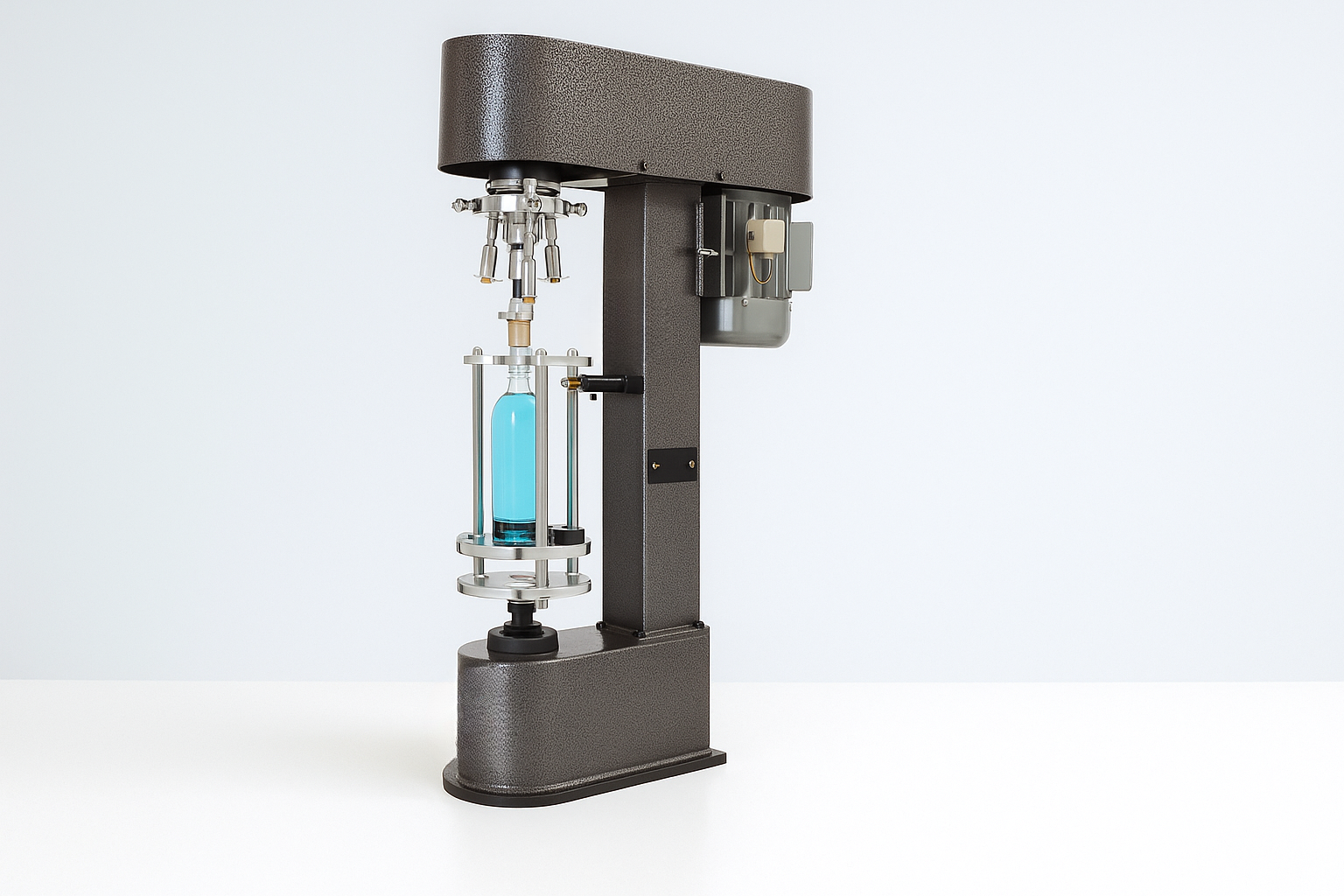

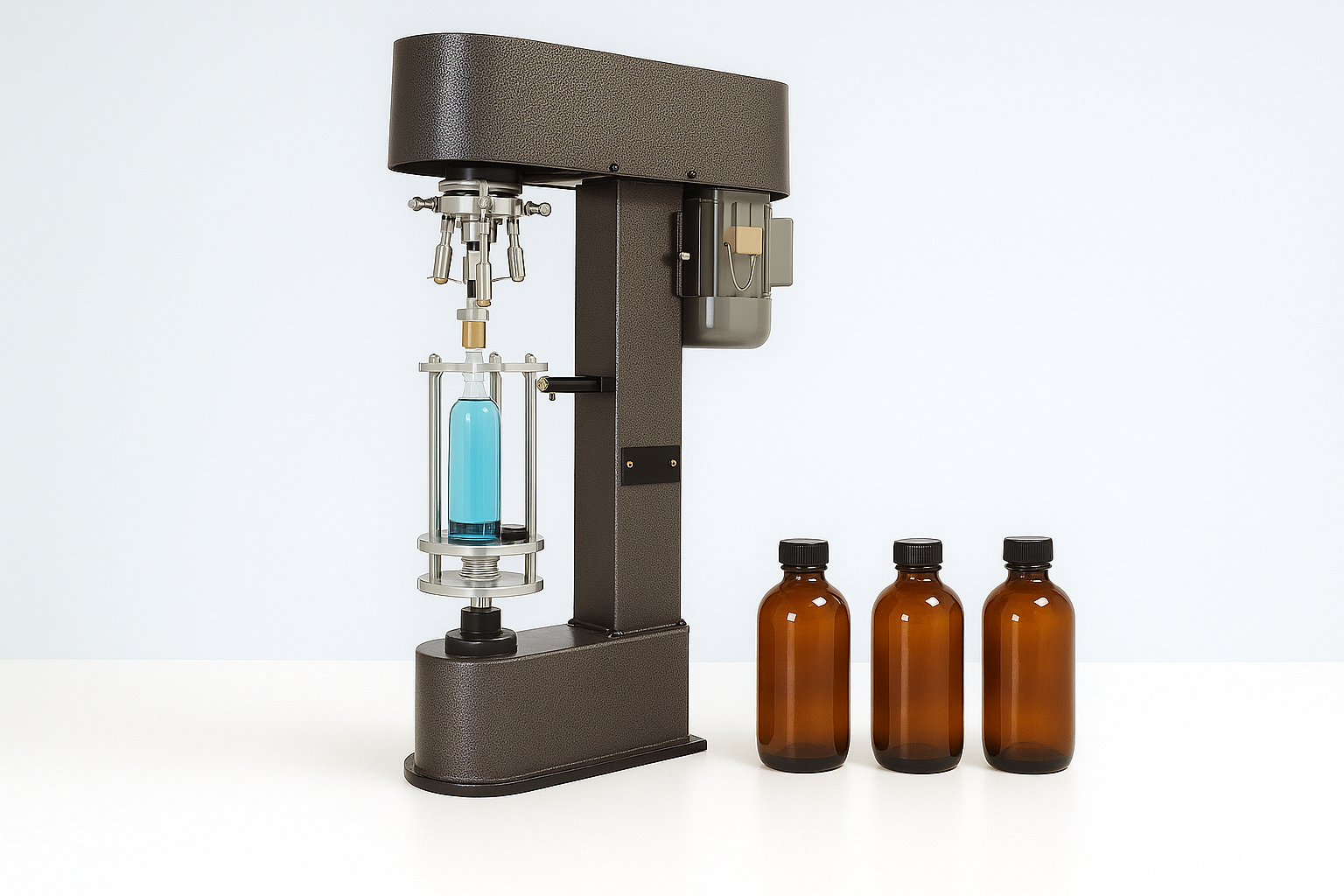

Semi-Automatic Cap Sealing Machine

1. Integrates the mechanical efficiency and operator control.

2. Most appropriate in medium-sized business organizations that require flexibility in production.

3. Balances cost-effectiveness and performance

.

Manual Bottle Capping Machine:

1. Compact and easy to use.

2. Ideal for startups or small-scale business.

3. Portable, budget-friendly and excellent for testing products lines.

ROPP Capping Machine (Roll-On Pilfer Proof)

1. ROPP cap, specially designed to fit the liquor, wine, and pharma bottles.

2. Creates tamper-evident seals while maintaining a clean aesthetic finish.

Induction Cap Sealing Machine

1. Bonds aluminum foils with the help of electromagnetic induction at bottle openings.

2. Ensures hermetic sealing without physical contact

3. Common in food, health, and personal-care industries.

Key Features to Look for in a Bottle Cap Sealing Machine

The decision to invest in a machine should be made after analyzing the specifications of the machine to suit your operational requirements. To distinguish between average and excellent machines, the latter have the following characteristics:

Speed and Output

Select a system that fits your production objectives in the day-to-day operations. There are automated bottle capping machines that can handle hundreds and even thousands of bottles in a given hour.

Compatibility & Versaitality

Instead, use a capping machine which can accommodate various cap styles, screw, snap-on, ROPP, or crown without significant modifications.

Ease of Operation

Easy-to-use control panels and digital displays ease the adjustments and reduce the downtime.

Durability and Construction Quality

The machines are made of food grade aluminum or stainless steel which is not corrosive and thus has a long service life.

Precision Sealing

Find torque control and sensor based alignment so that the closure will be consistent with all bottles.

Safety Systems

Stop switches of emergency nature, overloads and auto shutdowns increase safety of operators.

Advantages of Using a Bottle Cap Sealing Machine

Increased Production Efficiency

Automation of the capping process saves a lot of labor and time. This increases the productivity and order filling.

Superior Seal Integrity

All seals are homogenous, and no leaks or loss of the product occurs on the way. This trust boosts the brand image and customer confidence.

Cost-Effectiveness

Initial investment can be high, but looking at the reduction in the labor costs, low wastage and losses in rejection, the long-term payoff is great.

Scalability

Everything can be modified or expanded to a larger system, most machines work with either a semi-automatic or a fully automated line.

Adherence to Safety Standards

Today bottle cap sealing machines are implemented according to the GMP and CE standards and that way they comply with international packaging standards.

Applications Across Industries Of Bottle Cap Sealing Machines

Food and Beverage

Used in the sealing of the bottles of juices, water, sauces, and condiments. A bottle capping machine gives a hygienic, leak-free seal that is essential for the safety of the consumers.

Pharmaceuticals

Maintains airtight and tamperproof seals for syrups, suspensions and liquid medications

Cosmetics and Personal Care

Guarantees product protection for perfumes, essential oils, serums and lotions

Chemicals and Pesticides

Safely stores liquids, volatile or dangerous, to avoid spillages and contamination

Common Capping Challenges and Smart Solutions

| Challenge | Possible Cause | Solution |

| Cap Misalignment | Inaccurate positioning or cap feeder error | Use sensors and alignment guides |

| Loose or Leaky Seals | Inconsistent torque or worn components | Regular calibration and part replacement |

| Downtime | Lack of preventive maintenance | Schedule regular servicing |

| Irregular Bottle Shapes | Incompatible design or setup | Choose adaptable, servo-driven capping systems |

Maintenance Tips for Longevity

Regular Lubrication: Keep all moving parts well-lubricated to reduce friction and wear.

Routine Calibration: Ensures consistent torque and alignment.

Periodic Inspection: Check for worn belts, chucks, or sealing heads.

Clean After Each Run: Prevent residue build-up that can affect hygiene and machine accuracy.

Follow Manufacturer Guidelines: Adhere to prescribed service intervals for optimal performance.

How to Select the Ideal Bottle Cap Sealing Machine

It is crucially important to make decisions regarding the type of bottle cap sealing machine to use depending on your production requirements and packaging. Here’s a quick checklist:

Volume of production: Very high-speed automatic models are used in mass production; manual or semi-automatic models are used in smaller batches.

Type of Cap: Screw, ROPP, snap-on or cork -make sure that the machines are compatible.

Bottle Material: Glass or PET bottle can require varying torque or sealing pressure.

Budget & ROI: Consider operating costs, maintenance and scalability potential.

Space and Power Requirement: Make sure that your space facility can fit the machine in size and power requirement.

Ajanta Bottle: 44 Years of Packaging That Builds India’s Shelf Presence

With over 44 years of legacy in the Indian packaging industry, Ajanta Bottle has become more than just a packaging supplier—it is a trusted partner to brands looking to scale, differentiate, and lead through design.

From the early days of supplying classic glass containers for pharmaceuticals and household staples to now providing premium glass jars, lightweight bottles, and customized aluminum cans for food and beverage businesses, Ajanta has stayed ahead by understanding what packaging really means in a competitive market.

We have worked with countless Indian brands, both legacy and new-age, helping them:

-

Launch shelf-ready products with strong first-impression value

-

Shift from plastic to glass to enhance sustainability and consumer trust

-

Integrate packaging design with brand stories for premium perception

-

Optimize for retail stocking, e-commerce delivery, and food service convenience

Our in-house decoration unit, innovative packaging machinery under Akikai, and continuous investment in research and customer education (through platforms like PackSchool) make us uniquely placed to support packaging transformations that matter.

Whether it’s a cold-pressed juice in a sleek amber glass bottle or a handcrafted pickle in a heritage-inspired jar, Ajanta Bottle enables food and beverage brands to lead with packaging that speaks louder than words.

We don’t just supply containers.

We build packaging stories that sell.

Ready to create the perfect glass packaging for your brand?

Connect with us:

● Email at sales@ajantabottle.com

● Phone/Whatsapp: +91 9891098918

You can also shop from more than 500+ packaging solutions on www.ajantabottle.com – India’s first ever comprehensive packaging e-commerce portal.

For additional information, browse through our blog at https://www.ajantabottle.com/blog/ or subscribe to our latest updates through our social media channels,

*YouTube channel: https://www.youtube.com/c/Ajantabottle

*LinkedIn Page: https://www.linkedin.com/company/ajantabottle

*Facebook Page: https://www.facebook.com/glassbottleindia

*Instagram Page: https://www.instagram.com/ajantabottle

*Google Business Profile Manager: https://g.page/r/CXTH9MKpe2DuEBM/review