The pharmaceutical industry is a highly regulated industry, and as a consequence, packaging is not simply a matter of putting a product in a case; it is more like a continuation of the product in terms of identity, efficacy, and safety. With pharmaceutical manufacturers struggling to manage ever-increasing regulatory and media attention, heightened patient expectations, and an ever more environmentally-conscious market, a single packaging option has continued to demonstrate its value: the glass bottle.

This supports the ongoing shift towards pharmaceutical packaging.

The glass bottle, which had become a standard in medical packaging, is regaining its significance. It is the preferred choice of injectable drugs, sensitive formulations, as well as premium medicines, with unmatched sterility, impressive structural integrity, and increasing consumer acceptability. This blog discusses why, in spite of plastic and polymer innovations, the glass bottle is irreplaceable in pharma.

The Role of Glass Bottles in Pharmaceutical Packaging

Ever think of a medicine container as a superhero? If not, it’s time to change that perception because a glass bottle isn’t just packaging; it’s an active line of defense. In the pharmaceutical world, where the slightest compromise can mean therapeutic failure or patient harm, the glass bottle plays a vital role in preserving drug safety from production to consumption.

This supports the ongoing shift towards pharmaceutical packaging with amber glass bottle use in critical applications.

Shielding Against Environmental Villains

Glass bottles provide a strong defensive line against moisture, oxygen, light, and microbial contamination, all of which are established villains in active pharmaceutical ingredient (API) degradation. Sensitive compounds can be oxidized by even traces of moisture or oxygen, and light-sensitive formulations may be destabilized by UV rays exposure. The non-porous structure of a glass bottle ensures that these factors cannot penetrate through the barrier, and as such, it serves as a force-field of sorts around the medicine within.

This supports the benefits of using amber glass bottles in pharma.

Example: Such antibiotics as amoxicillin are quickly destroyed in a moist environment. Bottles made of glass do not have this risk, and provide an air and water-tight closure which increases shelf life and ensures therapeutic strength.

This emphasizes sterile pharmaceutical packaging.

Upholding Molecular Integrity

Glass bottles are chemically inert, unlike plastic containers, which could interact with APIs by migration or adsorption. This is so that the drug within is not contaminated or reactive to its original molecular structure. When used in critical treatments, e.g., in cases of cancer treatment or hormone-based drugs, this may be the distinction between life-saving outcomes and less than optimum outcomes.

This highlights the amber glass bottle advantages in pharmaceutical packaging.

Hard Truth: Certain plastic bottles may take up lipophilic (fat-soluble) molecules from a formulation and change the drug concentration in a formulation in a subtle manner over time. This danger is eliminated with a glass bottle.

This aligns with pharmaceutical packaging trends featuring amber glass bottles.

Global Safety Standard Compliant.

Regulatory agencies such as the FDA, EMA, and WHO point out the container-closure integrity as a fundamental concept of drug safety. A fine glass bottle (particularly when a tight cap or rubber stopper is used) meets stringent sterility, contamination resistance, and extractables/leachables requirements.

This supports innovations in amber glass bottle packaging.

Insight: WHO guidelines on Good Storage Practices for Pharmaceuticals (GSP) cite glass as the ideal package material to be used in injectable drugs and suspensions in tropical regions since it displays better stress resistance.

This confirms why amber glass bottle packaging remains the safest choice in pharmaceutical packaging.

Sterility at the Core: The Uncompromising Standard of Glass

The Inert Nature of Glass

Glass is chemically inert. Unlike plastics, which may leach chemicals or interact with active pharmaceutical ingredients (APIs), the glass bottle offers a non-reactive environment. This is especially crucial for biotech drugs and antibiotics, where even minimal interaction can degrade drug efficacy.

This showcases the core of pharmaceutical packaging solutions using amber glass bottle materials.

Superior Barrier Properties

A glass bottle creates an impermeable barrier to gases and vapors, including oxygen and water vapor, critical culprits in drug degradation. In contrast, high-barrier plastics often fall short over time, particularly in humid environments.

This highlights why amber glass bottle packaging is trusted in pharmaceutical packaging for sensitive drugs.

Case Study – Genentech’s Biologics

Genentech, a leader in biotech therapies, shifted multiple biologic drug packaging formats from polymer to Type I borosilicate glass bottles after discovering minor but measurable leaching of stabilizers from plastic containers. Post-transition, stability test results showed a 35% increase in product shelf life.

This is a strong example of pharmaceutical packaging with amber glass bottle superiority.

Hard Truth: Even the best multilayer plastics (like EVOH blends) allow minimal gas permeation over time. That’s acceptable for food, but not life-saving medication.

Strength Beyond the Surface: Physical Protection and Chemical Resistance

Structural Integrity in Transit and Storage

Pharmaceutical supply chains are complex. Products move across climate zones, encounter mechanical shocks, and remain in storage for months. A well-manufactured glass bottle especially those tempered or Type I borosilicate maintains its form and protection without warping, degrading, or reacting.

This supports the long-term performance of amber glass bottle packaging in pharmaceutical packaging logistics.

Resistance to Solvents and Acids

Pharmaceutical preparations often contain solvents like ethanol, glycerin, or saline. Over time, these can erode certain plastic materials or cause micro-extraction of plasticizers. A glass bottle maintains its integrity regardless of the liquid it holds.

This reinforces why choosing amber glass bottles for pharmaceutical packaging prevents contamination.

Data Insight: In a 2023 study by the European Medicines Agency, breakage rates of tempered glass bottles were only 0.007% across 1 million units, compared to 0.36% for high-density polyethylene (HDPE) during global transit simulations.

Safety and Trust: The Regulatory and Human Perspective

Preferred by Pharmacopeias and Regulatory Bodies

The U.S. Pharmacopeia (USP) and European Pharmacopoeia consistently rate Type I glass bottles as the gold standard for injectable drugs and sensitive medications. For many APIs, glass is not an option it’s a mandate.

This aligns with how amber glass bottles support regulatory-grade pharmaceutical packaging.

Regulatory Insight: The USP <660> and EP 3.2.1 specifically classify glass containers in three categories, with Type I (borosilicate) required for parenterals and heat-sterilized drugs.

Patient Trust and Brand Image

Consumers associate glass bottles with purity, heritage, and premium quality. This perception directly boosts a pharmaceutical brand’s trust and recall.

This strengthens the emotional connection enabled by amber glass bottle packaging in pharmaceutical packaging.

Case Study – Himalaya Herbal Pharmaceuticals

In 2021, Himalaya shifted 70% of its syrup and liquid drug portfolio to glass bottles for both domestic and export markets. The shift was not regulatory—it was strategic. A brand survey afterward showed a 48% improvement in product trust scores among urban buyers.

Types of Glass Used in Pharmaceutical Packaging

Selecting an appropriate type of glass is not only a matter of containment, but rather a matter of compliance, compatibility, and chemical performance. Pharmaceutical use requires material science to be followed strictly. Glass bottles are differentiated into various types, which are distinguished by their composition, reactivity, and purpose of use, and each type plays a particular role in the assurance of patient safety.

This helps explain the precision needed in pharmaceutical packaging choices, especially when using amber glass bottles.

Type I (Borosilicate) Glass – The Industry Gold Standard

Type I glass bottles are made from borosilicate glass, renowned for their exceptional chemical durability, thermal shock resistance, and overall inertness. This inevitably makes them the premier and sole option when it comes to parenteral (injectable) medications, high-sensitivity biologics, vaccines, or acidic or alkaline substances.

They are superior due to the addition of boron oxide, which reduces the coefficient of thermal expansion as well as increases resistance to water attack and rapid temperature changes. Type I glass bottles are also stable in autoclaving conditions or when subjected to a freeze-drying (lyophilization) process without delamination or microcracks, which frequently occur with most polymer-based containers.

This continues to position Type I glass bottles at the forefront of pharmaceutical packaging involving amber glass bottles.

Why it matters: For injectables, even a microdose of leachables can spell failure. Borosilicate glass ensures zero compromise. That’s why every major vaccine manufacturer from Pfizer to Serum Institute uses Type I glass bottles for critical dose containment.

This reinforces the essential nature of amber glass bottle packaging in safe pharmaceutical packaging.

Type II Glass – Treated Soda-Lime Glass with Enhanced Resistance

Type II glass bottles are made of soda-lime-silica glass; however, the glass is treated, typically by sulfur treatment, to dealkalize the glass surface. This modification increases the hydrolytic resistance of the glass, and it can be used in aqueous solution as well as in some acidic or neutral parenteral solutions.

While not as inert as Type I, Type II glass is a cost-effective compromise for manufacturers working with less sensitive formulations that still require parenteral delivery.

This supports cost-effective amber glass bottle options for general pharmaceutical packaging.

Use Case: Multivitamin injections, saline-based solutions, and large-volume IV drugs often come in Type II glass bottles where cost-efficiency and chemical compatibility can be balanced effectively.

Type III Glass – Economical but Limited in Scope

The most typical form of soda-lime glass is the Type III glass bottle, which is commonly used in oral solid dosage forms, cough syrups, antacids, and nutraceuticals. They are much less hydrolytically resistant than Type I or II and cannot be used as parenteral or in reactive formulations.

With that said, they are much more affordable and easier to process, so they are a perfect fit in OTC pharmaceuticals and consumer health products where the requirements on sterility and chemical resistance are not as critical to the mission.

Amber glass bottles of this type are still widely used in pharmaceutical packaging for supplements and syrups.

Industry Practice: Many ayurvedic brands, pediatric syrups, and multivitamin tonics still rely on Type III glass bottles often amber-tinted to offer added UV protection.

Amber Glass – UV Protection Across Types

Irrespective of the glass bottle being Type I, II, or III, the addition of iron oxide and sulfur compounds creates amber-colored glass. This tint is specifically useful in protecting light-sensitive formulations (such as riboflavin or chlorpromazine) against ultraviolet degradation.

This is a powerful feature that makes amber glass bottles ideal for light-sensitive pharmaceutical packaging formulations.

Conclusion: Glass Type is Not One-Size-Fits-All

Selecting the appropriate glass bottle type in pharmaceutical packaging isn’t just about cost it’s a decision that affects stability, compliance, and ultimately, patient safety. Type I borosilicate glass will remain the premium choice for injectable and biologically sensitive drugs. However, Types II and III offer essential flexibility in the market for manufacturers who need to scale without compromising performance too heavily.

Understanding the differences ensures pharma companies make informed choices that are aligned with both regulatory expectations and therapeutic demands.

This underlines the scientific and strategic approach needed in pharmaceutical packaging with amber glass bottles.

Debunking the Myths: Fragility, Weight, and Cost

Is Glass Too Fragile?

Glass breakage is a concern, but only when packaging is poorly designed or handled. Today’s pharmaceutical glass bottles are often tempered, coated, or packed with secondary protective materials to mitigate breakage.

This innovation supports the continued use of amber glass bottles in high-performance pharmaceutical packaging.

Innovation Alert: Companies like Schott and Gerresheimer have introduced anti-shatter coatings that reduce breakage by 90% during falls under 1.5 meters.

This advancement helps secure fragile medicines in amber glass bottle packaging for pharmaceutical packaging solutions.

Is Glass Too Heavy?

Weight matters in logistics but so does performance. While plastics may weigh less, the incremental logistics cost is often offset by reduced spoilage, improved shelf-life, and fewer regulatory issues.

This supports the practical preference for amber glass bottle packaging in global pharmaceutical packaging supply chains.

Is Glass More Expensive?

Yes, upfront costs are higher. But factor in long-term metrics like shelf stability, customer trust, compliance costs, and reduced risk of recalls and the glass bottle becomes a value-driven choice.

Hard Truth: In 2022, a leading Indian pharma company had to recall 2.4 million units of a vitamin syrup packaged in plastic due to contamination suspicions. The cost? ₹6.2 crores. Switching to glass could have avoided it entirely.

This is a compelling example of the long-term cost advantage of using amber glass bottles in pharmaceutical packaging.

Smart, Slim, and Secure: The New Era of Innovation in Pharmaceutical Packaging

The pharmaceutical industry is not only experiencing a formulation revolution, but it is also experiencing a material revolution, particularly in the manufacturing process, strengthening and ensuring the security of the glass bottles. With the convergence of compliance, logistics, and counterfeiting threats, next-gen innovation in glass bottle technology is taking those questions to that plastic can never truly have the answers.

This positions pharmaceutical packaging innovation firmly in favor of amber glass bottle systems.

Lightweighting Without Losing Integrity

Traditionally, glass was associated with bulk and breakability. But with precision molding and advanced annealing processes, that paradigm has changed. Pharmaceutical glass containers are now thinner, lighter, and just as strong if not more so than their predecessors.

“Lightweight glass bottles are not just about saving weight they’re about improving handling, cutting freight costs, and reducing environmental impact without compromising safety.”

This directly supports ESG-aligned pharmaceutical packaging choices using amber glass bottles.

Case Highlight: SGD Pharma’s ‘Pluma’ Breakthrough (2023)

Introduced in early 2023, Pluma bottles are engineered using cutting-edge IS machines and advanced glass composition.

Achieved 18% weight reduction on average across their parenteral line while maintaining:

-

ISO 8362 compliance

-

Breakage resistance equal to traditional formats

-

Type I borosilicate chemical properties

Operational Impact:

Pharmaceutical exporters using Pluma report a 14–16% reduction in freight costs per shipment, especially across air cargo routes to Europe and Japan.

Reduced raw material usage contributes to lower carbon footprints, aligning with ESG goals demanded by many hospital procurement departments.

This is a leading example of innovation in amber glass bottle manufacturing for pharmaceutical packaging on a global scale.

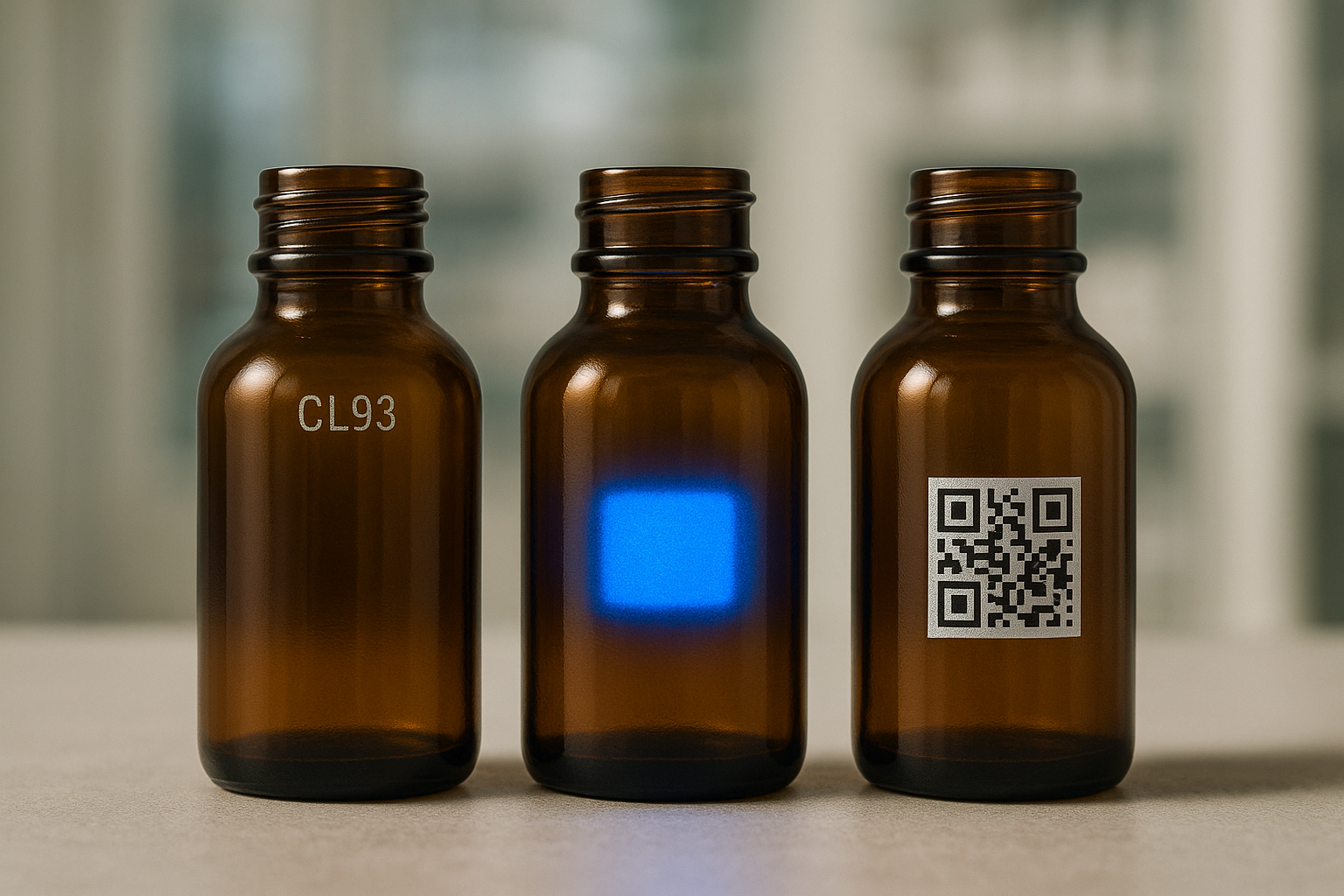

Smart Glass: Your First Line of Defense Against Counterfeiting

In an era where counterfeit drugs cause over 1 million deaths globally each year (WHO, 2021), pharmaceutical packaging can no longer be passive. The next generation of smart glass bottle technology actively protects the product and the patient.

This redefines the purpose of amber glass bottle packaging within pharmaceutical packaging security standards.

Key Features Now Seen in High-Security Glass Bottles:

-

Laser-Etched Batch Numbers: Permanent, non-removable, resistant to solvents and physical wear

-

UV-Reactive Inks: Invisible to the naked eye, visible only under UV scan in pharmacies and border control

-

Embedded QR/NFC Codes: Scannable by both regulators and patients, enabling end-to-end traceability and post-market surveillance

“These anti-counterfeit measures are native to glass. You cannot engrave plastic with the same permanence, nor can you prevent it from distortion during heat exposure.”

Case Study: Novartis ‘SecurePack’ Injectable Vials

In 2022, Novartis launched a pilot program in Southeast Asia to combat a growing threat counterfeit vials of its high-demand anti-viral injectables were circulating in black markets. The counterfeits used clear PET bottles with fake paper labels.

What They Did:

-

Shifted to pharma-grade amber glass bottles

-

Used laser-etched UV authentication inks directly on the bottle body

-

Integrated SecurePack QR codes, which required cloud verification upon scan

-

Rejected any unlabeled or paper-labeled variants at distribution centers

Results After 18 Months:

-

74% reduction in counterfeit detection reports across five Southeast Asian countries

-

Zero recalls due to packaging-related concerns

-

Higher pharmacist and physician trust, resulting in a 22% increase in repeat hospital procurement

“Plastic can be faked. Labels can be forged. But smart glass speaks for itself and can’t be silenced.”

This showcases how pharmaceutical packaging with amber glass bottles is evolving as a frontline defense.

The Road Ahead: What to Expect in the Next Wave

Glass bottle innovation in pharmaceutical packaging is heading into predictive packaging, where smart materials will alert to:

-

Temperature excursions

-

UV exposure during transit

-

Cap tampering

-

Geolocation during export

These features redefine the role of amber glass bottle containers in intelligent pharmaceutical packaging systems.

Ajanta Bottle is already exploring:

-

Blockchain-linked glass serialization

-

On-demand laser customization for batch traceability

-

Color-coded, weight-reduced vial systems for oncology and pediatrics

These advancements demonstrate Ajanta’s commitment to future-ready pharmaceutical packaging with amber glass bottles at the core.

Glass at the Core: Dominant Use Cases Across Pharma & Health

- Injectables & Vaccines

Glass remains indispensable in this category. Type I borosilicate glass vials are mandatory due to their superior chemical resistance, non-reactivity, and thermal shock stability. These vials prevent drug interaction, ensuring the stability and efficacy of sensitive biologics, vaccines, and injectable solutions, especially under extreme temperature variations during transportation and storage.

This highlights how pharmaceutical packaging thrives on the unmatched properties of amber glass bottles. - Syrups & Suspensions

Glass, especially amber-colored bottles, is widely used for syrups and suspensions. The amber tint provides UV protection, which is crucial for preserving light-sensitive formulations like cough syrups and iron supplements. Moreover, the impermeable nature of glass ensures that volatile contents don’t leach, oxidize, or degrade over time.

A perfect application of amber glass bottle packaging in over-the-counter pharmaceutical packaging. - Ayurvedic and Herbal Medicines

In traditional and herbal medicine packaging, clear glass bottles are a symbol of purity, transparency, and trust. Ayurvedic and herbal product brands prefer glass to reflect the natural and unadulterated nature of their ingredients. The inert surface of glass also ensures that plant-based formulations retain their therapeutic qualities without reacting with the packaging.

This is why amber glass bottles remain integral to trusted herbal pharmaceutical packaging. - Ophthalmics

Eye care products such as eye drops, lubricants, and ophthalmic solutions are packaged in small-dose sterile glass containers. These come with dropper caps or pipettes that allow precise dosage. Glass ensures 100% sterility and prevents microbial contamination, a critical factor in ophthalmic applications.

Amber glass bottle usage in pharmaceutical packaging ensures both hygiene and precision. - Diagnostics & Blood Collection

Glass dominates diagnostic sampling due to its excellent vacuum retention and barrier properties. Vacuum-sealed glass tubes are used for blood collection, ensuring minimal contamination and consistent test results. Their high-dimensional stability and resistance to deformation under pressure make them the gold standard in clinical labs and pathology centers.

This clinical reliability cements the role of amber glass bottles in diagnostic pharmaceutical packaging. - Homeopathy & Tinctures

Homeopathic remedies and tinctures, often alcohol-based, are ideally stored in glass dropper bottles. Glass does not react with alcohol or essential oils and ensures that the potency of the remedy remains intact. The use of amber or cobalt blue glass also provides light protection.

This ensures potency and safety in pharmaceutical packaging for delicate formulations using amber glass bottles. - Biotech & Laboratory Use

In R&D environments and biotech labs, glass containers, beakers, and vials are preferred for their resistance to sterilization processes like autoclaving and dry heat. Their transparency allows clear observation of reactions and measurements, critical for analytical precision.

A specialized yet growing area where amber glass bottles support high-end pharmaceutical packaging standards. - Nutraceuticals & Dietary Supplements

Many liquid nutraceuticals—especially those rich in iron, vitamins, or botanical extracts—are stored in amber or flint glass bottles. Glass ensures longer shelf life, no leaching of toxins, and compliance with FDA and WHO guidelines for active formulation protection.

This reaffirms amber glass bottle packaging as a secure and compliant form of pharmaceutical packaging.

At Ajanta Bottle, we understand that in the world of pharmaceuticals, packaging is not just a container, it’s a promise of safety, purity, and precision. That’s why we remain deeply committed to advancing amber glass bottle technologies that meet the highest global standards of pharmaceutical packaging. With over four decades of expertise, Ajanta Bottle continues to empower pharmaceutical brands with packaging solutions that are sterile, regulatory-compliant, and future-ready. Whether it’s for injectables, syrups, herbal medicines, or biotech applications, our amber glass bottles are engineered to protect what matters most- human health and your brand’s integrity.

Ready to create the perfect pharmaceutical packaging for your brand?

Connect with us:

● Email at sales@ajantabottle.com

● Phone/Whatsapp: +91 9891098918

You can also shop from more than 500+ packaging solutions on www.ajantabottle.com – India’s first ever comprehensive packaging e-commerce portal.

For additional information, browse through our blog at https://www.ajantabottle.com/blog/ or subscribe to our latest updates through our social media channels,

*YouTube channel: https://www.youtube.com/c/Ajantabottle

*LinkedIn Page: https://www.linkedin.com/company/ajantabottle

*Facebook Page: https://www.facebook.com/glassbottleindia

*Instagram Page: https://www.instagram.com/ajantabottle

*Google Business Profile Manager: https://g.page/r/CXTH9MKpe2DuEBM/review