In the modern competitive world of manufacturing, the choice of liquid filling machine is a key strategic choice that has a direct bearing on the efficiency of production, quality of products and profitability. You need to package water, edible oil, shampoo, honey, lubricants, or sauces and the result of your filling system is what defines consistency, speed, and brand reliability. Since small-scale companies operate with semi-automatic systems to high-speed automated filling lines of bottles, companies need to match equipment with the type of products to be made, objectives of production, and future expansions. This guide is an analysis of the key considerations to enable you in selecting a liquid filling solution that spurs the operations excellence and scalable success.

First Let’s Understand What Is a Liquid Filling Machine?

A liquid filling machine is a filling machine that is used to fill bottles or containers with a known amount of liquid, which should be filled accurately every time. It helps to minimize wastes, time, enhance hygiene and enable scalable production over manual filling.

Identify Your Liquid Type (Viscosity + Behavior)

This is the biggest mistake people make:

They buy a filling machine first… and then try to “make it work” for their liquid.

In reality, liquid behavior decides everything.

You must classify your product into one of these:

1) Thin liquids (water-like)

Examples:

- drinking water

- toner

- rose water

- sanitizer

- vinegar

Best machines:

- gravity filling machine

- overflow filling machine

- pump filling machine (optional)

2) Medium viscosity liquids (oil-like)

Examples:

- edible oil

- hair oil

- essential oil blends

- lubricant oil

Best machines:

- piston filling machine

- pump filling machine

- servo filling machine (premium accuracy)

Oil requires drip control.

That’s why a proper oil filling machine must use:

- clean shutoff

- correct nozzle diameter

- anti-drip nozzle

3) Thick / viscous liquids

Examples:

- shampoo

- lotion

- honey

- sauces

Best machines:

- piston filling machine

- servo piston systems

- strong pneumatic filling systems

This is where a viscous liquid filling machine becomes essential.

A shampoo filling machine and a honey filling machine are usually piston-based for accuracy and flow control.

Choose the Right Automation Level

Most businesses get automation wrong in one of two ways: they either overspend too early on capacity they don’t yet need, or they under-invest and end up battling daily production bottlenecks, inconsistencies, and rework. The right automation level is simply the one that matches your current output targets, manpower reality, and quality expectations—while staying scalable for the next stage of growth. Let’s simplify it

Manual liquid filling machine

A manual liquid filling machine is a simple, operator-controlled solution that dispenses precise volumes without complex automation. Ideal for brands that need flexibility and low setup cost. This liquid filling machine is best for testing, micro-batches, and small production runs of 50–200 bottles/day where quick changeovers and consistent fills matter most. You can explore the specs on our website and shortlist what matches your bottle type and liquid

Semi-automatic liquid filling machine

A semi-automatic liquid filling machine is the sweet spot for businesses that have moved beyond trials and need dependable, repeatable filling every day without jumping straight into fully automated lines. It’s best for growing brands, regular daily production. This is the most practical ROI stage for most B2B owners. You can explore the specs on our website and shortlist what matches your bottle type and liquid

Calculate Your Real Output Requirement (BPM)

A filling machine’s speed is not what the brochure says.

Real speed depends on:

- viscosity

- bottle size

- nozzle count

- operator skill

- cleaning and changeover time

From Small Batches to High Output: Akikai Liquid Filling Setups

Most B2B buyers don’t need 50 different filling machines, they need the right configuration that matches their production stage and liquid type.

At Akikai, we’ve simplified the selection into a few proven liquid filling machine setups used by brands across oils, water-based liquids, and viscous products like shampoo, honey, and sauces.

Here’s a clear breakdown to help you shortlist faster

Digital Single-Head Liquid Filling Machine (Best for Small Batch + Multi-SKU)

This setup is commonly used by startup brands, cosmetic and oil brands, and businesses launching multiple SKUs. It works especially well when your output is limited, you need flexibility in production, and you frequently change bottle sizes.

A single-head digital liquid bottle filling machine is especially useful for:

- perfumes

- toners

- essential oils

- sanitizer

- thin oils

You’ll find this setup in machines like a single-head digital liquid filling machine (commonly priced for entry-level manufacturing). This single-head digital setup is a smart first step reliable for daily small-batch production today, and easy to upgrade from as demand grows.

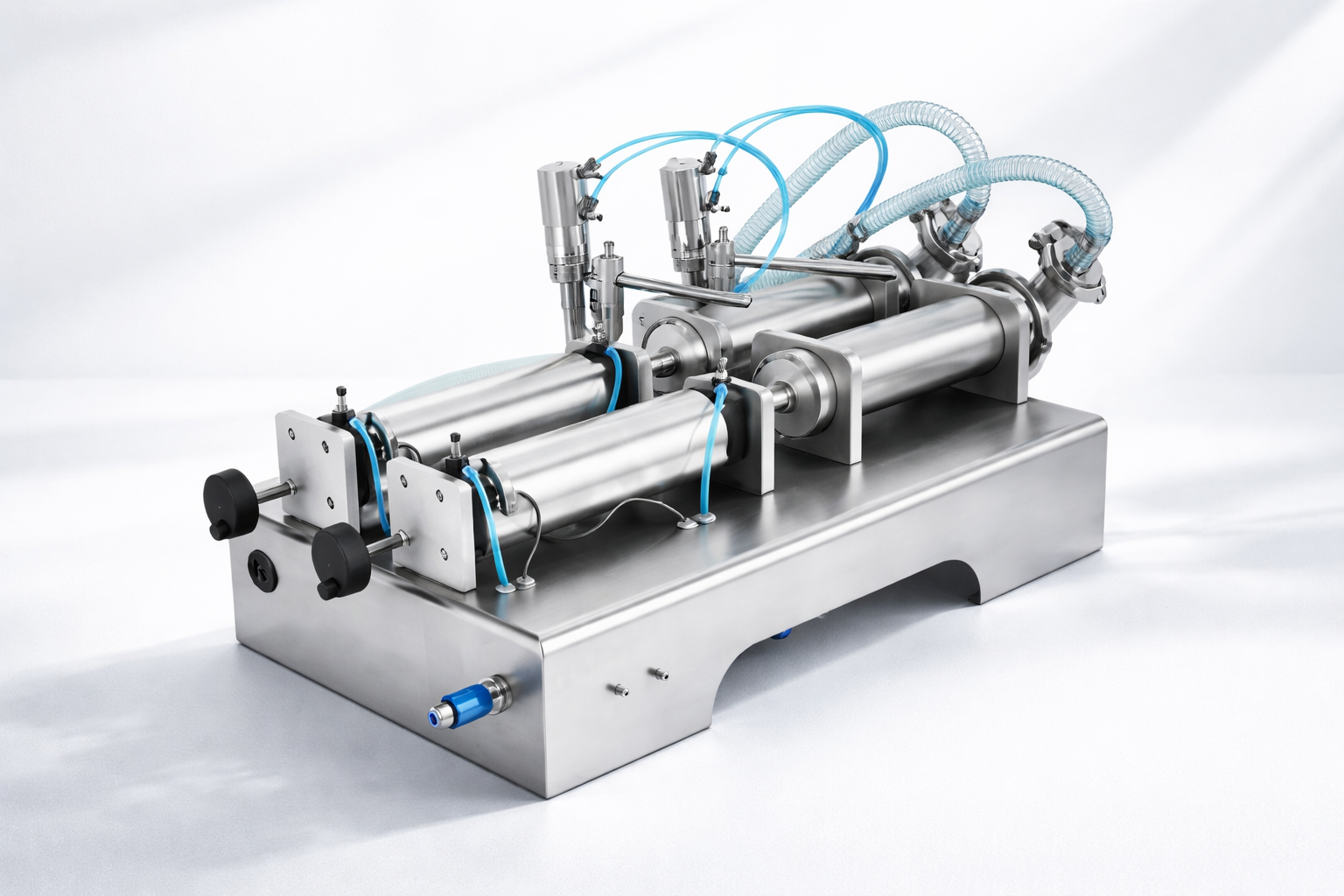

Digital Double Nozzle Liquid Filling Machine (Best for Speed Without Complexity)

Once businesses begin filling orders daily, the first bottleneck is almost always speed and that’s exactly where a double-nozzle digital liquid filling machine becomes a smart upgrade. It boosts output immediately with two synchronized fills per cycle, while keeping operations simple and clean no compressors, no pneumatic systems, and no complicated maintenance routines

A double-nozzle digital liquid filling machine solves that without adding:

- compressors

- pneumatic systems

- complex maintenance

It’s widely used for:

- water-like liquids

- oils

- cosmetic liquids

A common example is a double nozzle digital liquid filling machine, which fills two bottles simultaneously and increases daily output.

Pneumatic Single Head Liquid Filling Machine (Best for Oils + Viscous Liquids)

When brands step into thicker, higher-viscosity products or simply need more dependable performance at higher daily volumes a Pneumatic Single Head Liquid Filling Machine becomes the more reliable choice.

A pneumatic single-head filling machine is widely chosen for:

- edible oil filling machine requirements

- lubricant oil filling machine production

- shampoo filling machine setups

- Viscous Liquid Filling Machine Use Cases

This setup improves:

- filling accuracy

- consistency

- long-term durability

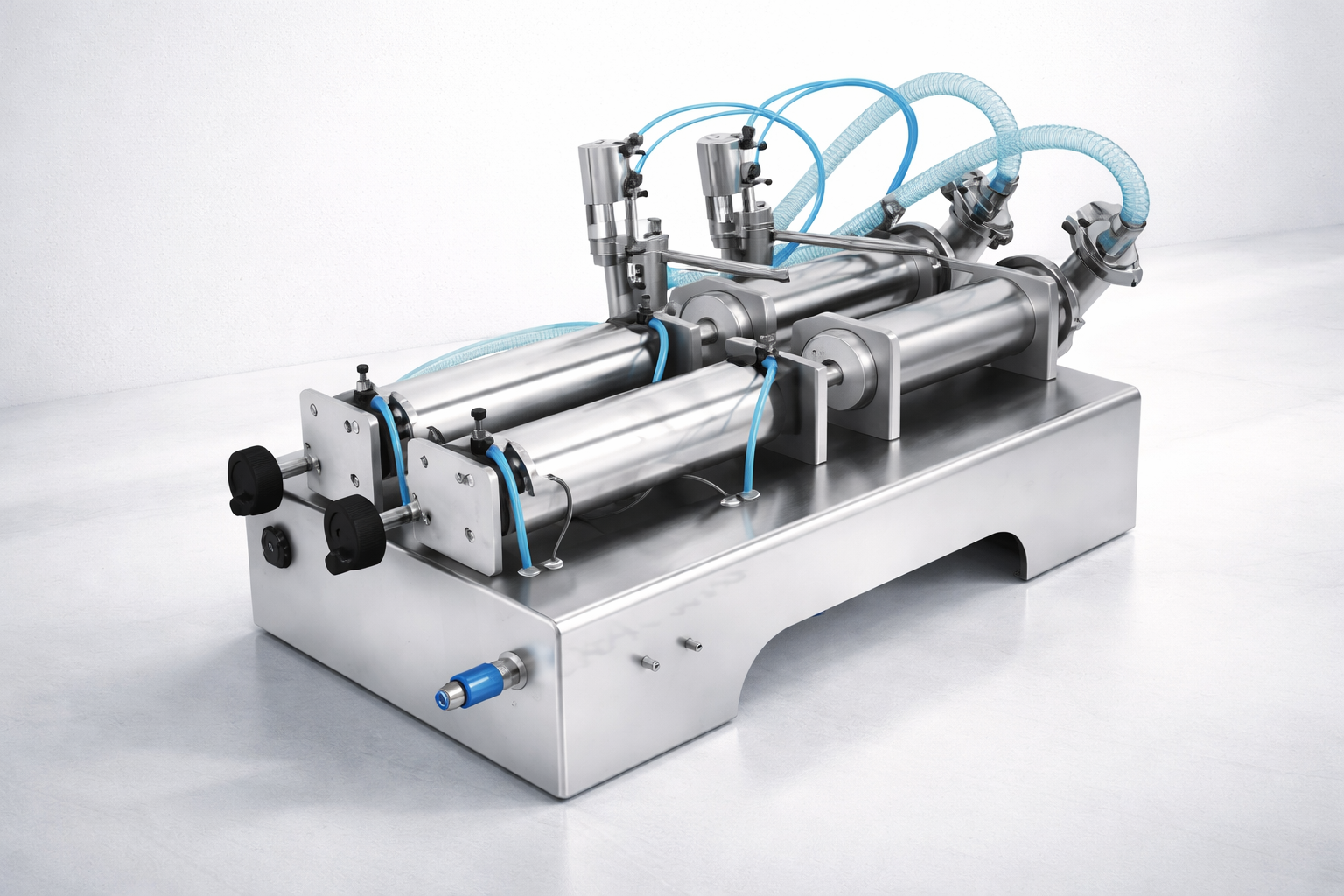

Pneumatic Double-Head Liquid Filling Machine (Best for Scaling Before Full Automation)

A Pneumatic Double-Head Liquid Filling Machine is the most practical next step when you’re ready to scale beyond manual filling—without committing to the cost and complexity of a fully automated line.

A pneumatic double head filling machine is ideal for:

- contract packers

- mid-to-high volume manufacturers

- brands filling multiple SKUs daily

It’s widely used for:

- sauce filling machine

- honey filling machine

- shampoo filling machine

- oil filling machine production

Quick Selection Table (Save This)

| Your Stage | Most Practical Setup | Best For |

| Launch / small batches | Digital single head | multi-SKU + low output |

| Growing output | Digital double nozzle | faster filling, simple |

| Serious daily production | Pneumatic single head | oil + viscous liquids |

| Scaling production | Pneumatic double head | higher output, reliable |

Nozzle Quality: The Difference Between Clean Bottles and Messy Bottles

Most people treat filling nozzles like accessories.In production, they decide everything.

Nozzle selection affects:

- Drip control

- Foaming

- Stringing

- Bottle cleanliness

For oils: Anti-drip nozzle is mandatory

If you’re selecting an oil filling machine, you must insist on:

- Anti-drip nozzle

- Clean shutoff

- Correct nozzle diameter

Without it, your bottle will look oily and cheap—even if your product is premium.

For foamy liquids: Bottom-up filling

Foamy liquids need:

- Controlled filling

- Slow start flow

- Bottom-up nozzle movement

Cleaning and CIP (Clean In Place): The Hidden Cost Most Buyers Ignore

A machine that fills 20 BPM is useless if it wastes 2 hours daily in cleaning. This is why B2B buyers must evaluate:

- CIP cleaning compatibility

- ease of dismantling

- cleaning time between SKUs

When CIP cleaning becomes important

CIP cleaning matters most for:

- Edible oil filling machine setups

- Food and beverage production

- Contract manufacturing

Even if you don’t need full CIP, a machine designed for easy cleaning saves time.

Bottle Compatibility and Bottle Size Changeover

A bottle filling machine must match your packaging.

Check:

- Bottle height

- Bottle stability

- Neck size

- Mouth diameter

- Glass vs PET

Bottle size changeover is a scaling issue

If you fill multiple SKUs, changeover time decides your efficiency.

Ask:

- Does it require tools?

- How long does it take?

- Can settings be saved?

Evaluate Total Cost (Not Just Filling Machine Price)

The biggest B2B mistake:

Buying a machine because it’s cheaper.

Low filling machine price often means:

- lower accuracy

- more wastage

- more downtime

- poor spares support

Always evaluate:

- service response

- spare parts availability

- warranty

- machine lifespan

Common Mistakes (And Fixes)

Mistake 1: Choosing the wrong filling principle

Fix: match liquid type to filling method.

Mistake 2: Ignoring nozzles

Fix: anti-drip nozzle for oils, controlled filling for foam.

Mistake 3: Underestimating cleaning time

Fix: check CIP cleaning options and dismantling time.

Mistake 4: Not planning for growth

Fix: choose scalable setups (double nozzle or pneumatic upgrades).

Mistake 5: Not planning bottle size changeover

Fix: ensure tool-free adjustments.

Pro Tips From B2B Manufacturing Experience

- Always test your liquid before purchase.

- Buy for 12 months ahead, not today.

- Semi automatic liquid filling machine setups often give best ROI.

- Anti-drip nozzle matters more than speed for oils.

- Focus on cleaning time and bottle changeover.

- Plan the bottle filling line (filling + capping + labeling).

Ajanta Bottle: 45 Years of Packaging That Builds India’s Shelf Presence

With over 44 years of legacy in the Indian packaging industry, Ajanta Bottle has become more than just a packaging supplier it is a trusted partner to brands looking to scale, differentiate, and lead through design.

From the early days of supplying classic glass containers for pharmaceuticals and household staples to now providing premium glass jars, lightweight bottles, and customized aluminum cans for food and beverage businesses, Ajanta has stayed ahead by understanding what packaging really means in a competitive market.

We have worked with countless Indian brands, both legacy and new-age, helping them:

-

Launch shelf-ready products with strong first-impression value

-

Shift from plastic to glass to enhance sustainability and consumer trust

-

Integrate packaging design with brand stories for premium perception

-

Optimize for retail stocking, e-commerce delivery, and food service convenience

Our in-house decoration unit, innovative packaging machinery under Akikai, and continuous investment in research and customer education (through platforms like PackSchool) make us uniquely placed to support packaging transformations that matter.

Whether it’s a cold-pressed juice in a sleek amber glass bottle or a handcrafted pickle in a heritage-inspired jar, Ajanta Bottle enables food and beverage brands to lead with packaging that speaks louder than words.

We don’t just supply containers.

We build packaging stories that sell.

Ready to create the perfect glass packaging for your brand?

Connect with us:

● Email at sales@ajantabottle.com

● Phone/Whatsapp: +91 9891098918

You can also shop from more than 500+ packaging solutions on www.ajantabottle.com – India’s first ever comprehensive packaging e-commerce portal.

For additional information, browse through our blog at https://www.ajantabottle.com/blog/ or subscribe to our latest updates through our social media channels,

*YouTube channel: https://www.youtube.com/c/Ajantabottle

*LinkedIn Page: https://www.linkedin.com/company/ajantabottle

*Facebook Page: https://www.facebook.com/glassbottleindia

*Instagram Page: https://www.instagram.com/ajantabottle

*Google Business Profile Manager: https://g.page/r/CXTH9MKpe2DuEBM/review