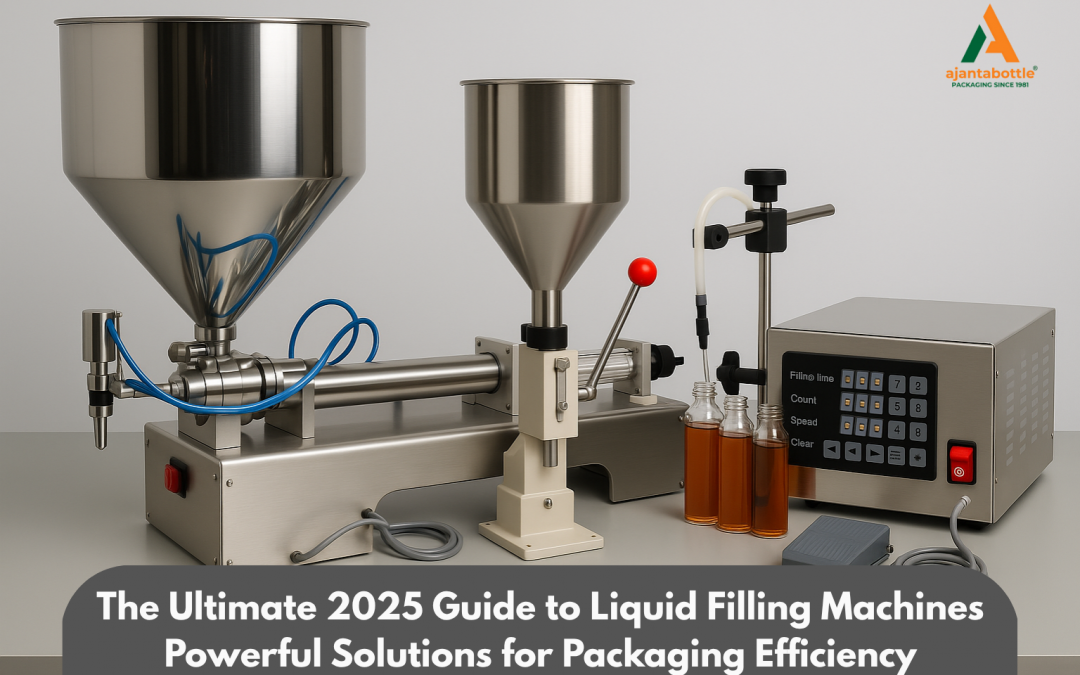

In the modern manufacturing environment, speed and accuracy are essentials no matter the type of product being produced; particularly in packaging liquids. Liquid filling machine is critical in filling all the bottles or containers correctly, hygienically, and without wastage. These machines automate, accelerate and bring consistency to your production lines as they are used in almost all industries such as perfumes and oils and also in beverages and pharmaceuticals.

No matter the size of your business (small business upgrading) or the scale of your organisation (large scale operation optimising), understanding how a liquid filling machine works, the tasks that the machine performs and how to control the machine, and what position it occupies in your process can transform your packaging efficiency and product quality.

What Is a Liquid Filling Machine?

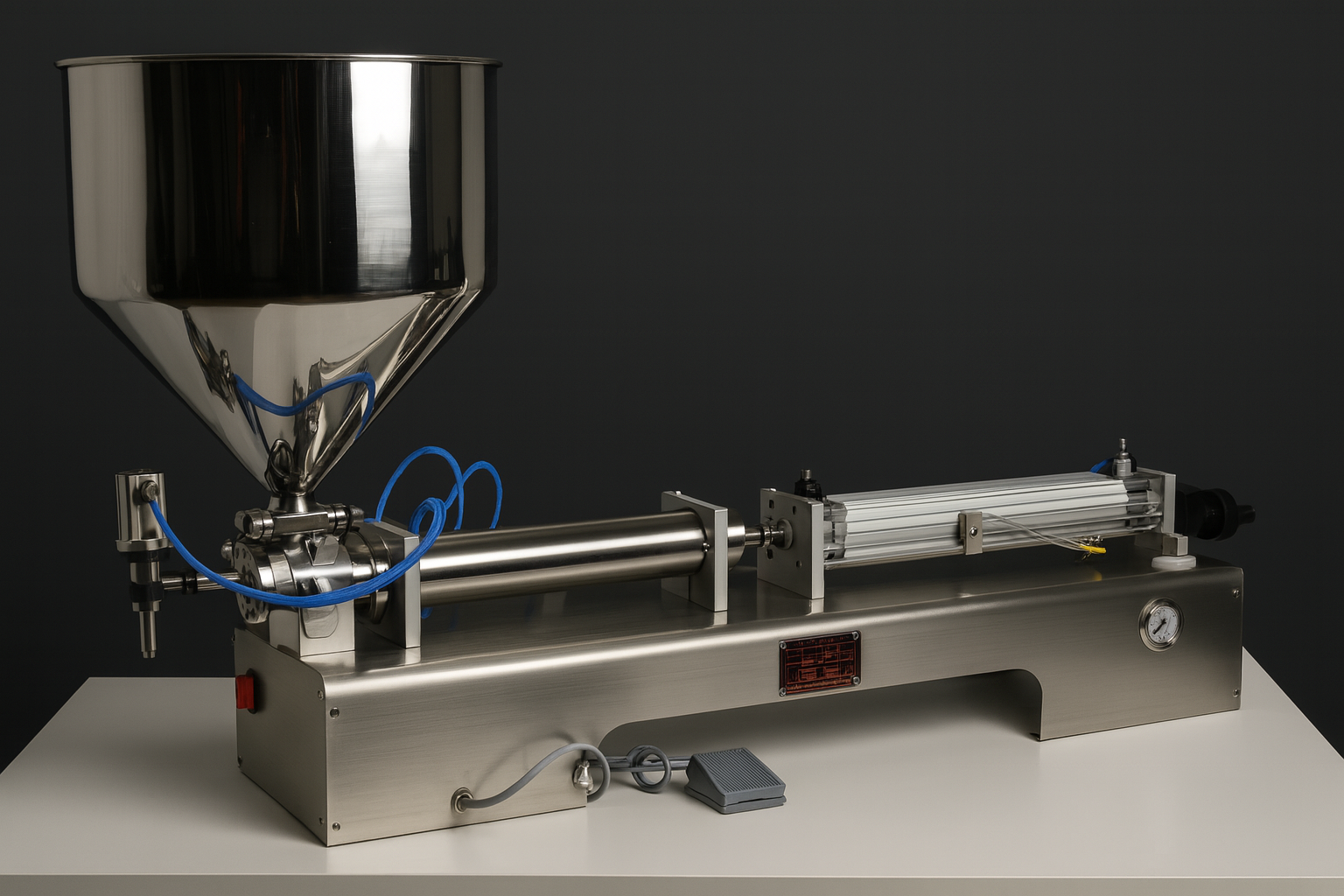

A liquid filling machine refers to a machine that is used to fill bottles, jars or other containers with liquids of various densities ranging between thin liquids such as water to thick liquids such as syrup or even shampoo. It counts and packs each container with the correct volume of product which can help make it right and consistent

Not every liquid filling machine can work with all types of liquids. As an example, the drinking water filler machine cannot be applied to cosmetic and the chemical-filling machine cannot be applied to food or medicines. Each kind of liquid should have a particular kind of machine, which is designed to fit in.

Modern manufacturing cannot be done without these machines as they save time, minimize waste, and preserve the quality of products. When selecting the correct machine you should take into consideration the following

In short, a liquid filling machine can assist in easier, faster, and more reliable production no matter what kind of liquid you are working with.

How Does A Liquid Filling Machine Work?

Although there are several types of filling machines, they all operate on the same principle of transferring a certain amount of liquid into a container. In automated systems, the bottles or jars are moved along a conveyor stopping under filling heads, which spray the product and proceed to the next stage. The filling method applied with the contents is determined by the texture of the liquid, the type of container and the accuracy of the filling.

Types of Filling Methods

The filling step is the easiest one to describe and the most difficult to master technically. It is the fundamental step which defines the type of equipment to use on a certain product.

Since liquids vary widely from thin, free-flowing solutions to thick, viscous substances or foamy mixtures, each requires a specific approach to measure and control the volume accurately. The container’s shape and material also affect which method is most efficient.

As liquids come in many forms, such as thin, free-flowing, or thick, viscous materials, or foamy mixtures, each of them will need a special method to control the volume accurately. The container’s shape and material also affect which is most efficient.

Common Working Principles

Gravity or Siphon Fillers

This type relies purely on gravity. A tank placed above the filling nozzles lets liquid flow downward when a valve opens, filling the container for a set period. After that time, the valve shuts automatically. Gravity fillers work best for thin, uniform liquids without suspended solids, such as water or syrups.

Overflow Fillers

Overflow systems aim to fill each bottle to the same visible level rather than by exact volume. They’re often used for transparent packaging because they make products look uniform on shelves. The machine fills until liquid spills over slightly, and the excess is redirected back into the main tank to avoid waste.

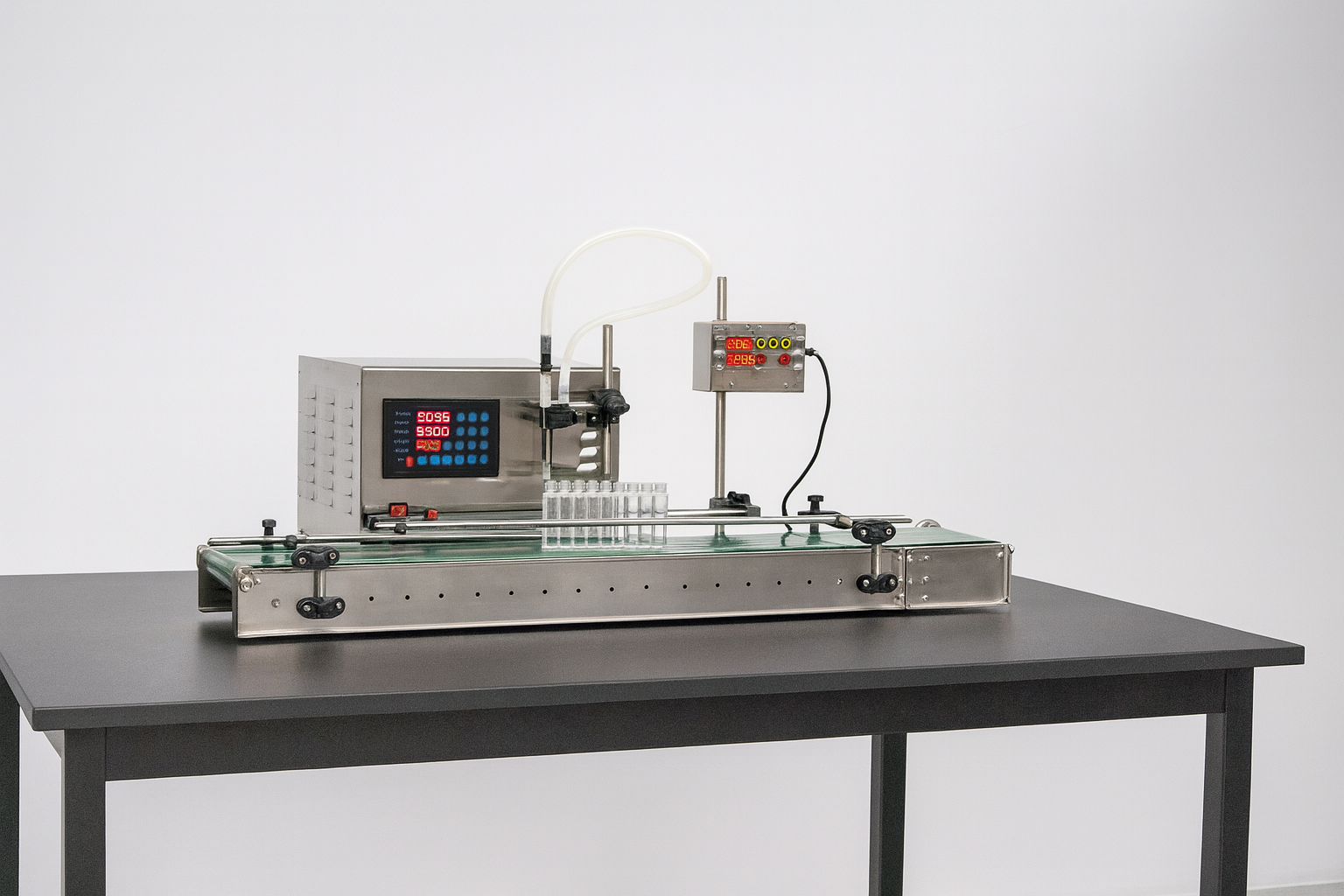

Piston Fillers

Piston fillers are suitable for thicker products such as creams, gels or sauces. In these machines, a piston and cylinder arrangement takes into consideration an exact quantity of liquid and expels it into the container. They offer excellent volume accuracy, suit both semi-automatic and automatic setups, and can be easily expanded with extra nozzles as production scales up.

Bottom-Up and Isobaric Pressure Fillers

In bottom-up filling, the nozzle will be inserted in the bottom of the container and the liquid will be released as the nozzle slowly goes up the container. This reduces splashing and foaming – so it is suitable to bubbly or frothy liquids.Isobaric fillers, typically applied to carbonated beverages, ensure that internal pressure is held by CO 2 as the carbonation does not go to waste. The liquid is controlled to flow gently down the sides of the container using a diffuser and any surplus gas is relieved using a pressure-controlled nozzle.

Pump Fillers

Pump filling systems use mechanical or peristaltic pumps to move liquid from the storage drum into the bottle. The fill quantity is usually controlled either by counting the number of pump rotations (pulse timing) or by pumping for a fixed time. While not as precise as piston fillers, they’re faster — making them suitable for larger containers where small volume deviations don’t matter much.

Check Weight Fillers

In this system, each container sits on a weighing platform that continuously monitors its weight during filling. Once the set weight is achieved, the flow stops automatically. This technique is particularly useful for large-format containers or applications where strict weight accuracy is essential.

How to Use a Liquid Filling Machine

Operating a liquid filling machine doesn’t have to be complicated. This is done through setup, calibration and quality checks.

Watch our full video on how to use a liquid filling machine –

Step 1: Prepare Your Product

Make sure that you filter your liquid and that it is not full of particles that will block nozzles.

Step 2: Choose the Right Container

Select containers compatible with your product material, size and shape.

Step 3: Set Up the Machine

- Adjust the fill volume

- Calibrate the machine based on liquid viscosity

- Place the conveyors and nozzles properly

Step 4: Test Fill

Test a few fill-ups to ensure that the volume is correct and there is no overflow.

Step 5: Start Production

When the test results are satisfactory, then change to automatic mode to go into full-scale production.

Step 6: Cleaning

After every production cycle, clean and sanitize the machine thoroughly (details in the next section).

Pro Tip:

Always monitor the pressure and flow rate. Even a small variation can lead to inconsistency in filling.

How to Clean a Liquid Filling Machine

Cleaning is not only about maintenance, but also about the safety and longevity of your machine

Step 1: Disconnect Power and Drain Product.

Switch off the power source and drain the tank. Be sure that all the remaining liquid is emptied.

Step 2: Disassemble Key Parts

Take off nozzles, pipes and pistons clean them individually

Step 3: Rinse with Water

Start with rinsing in water so as to take away all the visible residues.

Step 4: Use Cleaning Solution

Apply a low dose of detergent or a cleaning agent that is recommended in the industry. For food, cosmetic, or pharmaceutical applications, use CIP (Clean-In-Place) systems with sterile cleaning fluids.

Step 5: Sanitize and Dry

After cleaning, sanitize the inside surfaces and ensure that it is completely dry before reassembling.

Step 6: Reassemble and Test

Put the parts back together and do a test fill using clean water to ensure the parts are free of detergent or other contaminants.

The regular cleaning of the machine maintains the machine in an efficient condition, eliminates contamination, and increases its lifespan

Uses of Liquid Filling Machine

Liquid filling machines are used in nearly every industry that packages liquid or semi-liquid products. Let’s look at two popular applications:

Liquid Filling Machine for Perfume

Perfume packaging demands precision even a few drops can make a difference.

1. Perfume Liquid Filling Machine

The packaging of perfume requires a lot of accuracy even few drops can make a difference

A perfume liquid filling machine performs the various functions like –

- Deals with fragile and sensitive fluids.

- Provides micro-filling precision (often as low as 1ml).

- Perfect usage in small glass perfume bottles

These machines are commonly used in full perfume packaging, which may also include crimping machines, capping machines, and labeling machines.

2. Oil Liquid Filling Machine.

Viscosity is an important parameter when it comes to edible oils, lubricants or essential oils.

An oil liquid filling machine performs the various function like –

Uses piston or gravity filling methods

Can handle thicker consistencies without dripping.

Maintains hygiene, which avoids oxidation or contamination of oil.

This makes them necessary in industries like food processing, cosmetics, and automotive.

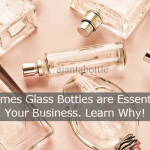

Liquid Filling Machine with Conveyor

The inclusion of a conveyor system in a liquid filling machine improves the production speed.

Why It Matters

The filling process of bottles or containers, including capping, labeling, and sealing will be automated by a liquid filling machine with a conveyor.

Key benefits

Continuous Flow: It removes the manual movement between stages.

Increased Productivity: Suited to large-scale production.

Less Labor: The operators are able to monitor more than one activity at the same time.

These systems can be customized from compact bench-top conveyors for small businesses to full-scale automated lines for industrial plants

Typical Setup

- The conveyor moves empty bottles to the filling station.

- The machine fills each bottle precisely.

- Conveyor transports filled bottles to the capping or labeling units

This setup ensures a seamless, synchronized workflow that boosts both speed and quality.

Liquid Filling Machine with Capping

A liquid filling machine with capping is an all-in-one packaging solution. It not only fills containers but also seals them immediately afterward, a crucial step for preserving product integrity.

Types of Capping Mechanisms

Screw Cappers: This type is used on threaded bottle top screw caps.

Crimp Cappers: Used in perfume and pharmaceutical bottles.

Press-on or Snap Cappers: Ideal for plastic or lightweight closures

Advantages

- Reduces manual handling and contamination risks

- Rapidly increases the speed of packaging lines.

- Ensures uniform, secure sealing

- This combination is especially useful in cosmetic, beverage, and chemical industries, where both accuracy and hygiene are vital.

- The combination is especially useful in cosmetic, beverage and chemical industries, where both accuracy and hygiene are important

Different Types Of Liquid Filling Machines

There are various types and each type must be known to select the appropriate one:

Manual Filling Machines – Cost-effective and ideal for startups or small batches.

Semi-Automatic Machines – Combine manual setup with automatic filling cycles.

Fully Automatic Machines – Offer high-speed, fully automated filling with conveyor and capping integration.

Each machine type serves a different scale and budget, ensuring flexibility across businesses.

Factors To Consider When Choosing A Liquid Filling Machine

When selecting the right machine for your production line, keep these factors in mind:

- Viscosity of Liquid – Determines whether you need a piston, gravity, or overflow filler.

- Container Type – Bottles, jars, or pouches may require different mechanisms.

- Production Volume – Helps decide between manual, semi, or fully automatic machines.

- Material Compatibility – Ensure the machine parts (like nozzles and seals) are compatible with your product’s chemical composition.

- Ease of Cleaning and Maintenance – Look for modular designs with quick-release components.

Maintenance Tips for Longevity

- Lubricate moving parts regularly.

- Inspect nozzles and seals weekly for leaks.

- Calibrate filling volume monthly.

- Replace worn-out gaskets or O-rings immediately.

Following a preventive maintenance routine can extend your machine’s lifespan by years.

Why Liquid Filling Machines Are a Smart Investment

Whether you’re in cosmetics, beverages, pharmaceuticals, or chemicals, investing in a liquid filling machine offers long-term benefits:

- Consistency: Uniform fills every time.

- Speed: Faster turnaround and higher output.

- Hygiene: Reduced contamination risk.

- Cost Savings: Less product waste and lower labor costs.

It’s a one-time investment that pays off through efficiency and professionalism.

Conclusion: The Future of Filling

As automation advances, liquid filling machines are evolving with smart sensors, AI integration, and IoT-based monitoring. Future systems will offer real-time diagnostics, predictive maintenance, and cloud-based performance analytics making them smarter, faster, and even more reliable.

If you’re in the business of packaging perfumes, oils, beverages, or pharmaceuticals this is the machine that defines precision.

A liquid filling machine doesn’t just fill bottles. It fills the gap between craftsmanship and efficiency.

Ajanta Bottle: 44 Years of Packaging That Builds India’s Shelf Presence

With over 44 years of legacy in the Indian packaging industry, Ajanta Bottle has become more than just a packaging supplier—it is a trusted partner to brands looking to scale, differentiate, and lead through design.

From the early days of supplying classic glass containers for pharmaceuticals and household staples to now providing premium glass jars, lightweight bottles, and customized aluminum cans for food and beverage businesses, Ajanta has stayed ahead by understanding what packaging really means in a competitive market.

We have worked with countless Indian brands, both legacy and new-age, helping them:

-

Launch shelf-ready products with strong first-impression value

-

Shift from plastic to glass to enhance sustainability and consumer trust

-

Integrate packaging design with brand stories for premium perception

-

Optimize for retail stocking, e-commerce delivery, and food service convenience

Our in-house decoration unit, innovative packaging machinery under Akikai, and continuous investment in research and customer education (through platforms like PackSchool) make us uniquely placed to support packaging transformations that matter.

Whether it’s a cold-pressed juice in a sleek amber glass bottle or a handcrafted pickle in a heritage-inspired jar, Ajanta Bottle enables food and beverage brands to lead with packaging that speaks louder than words.

We don’t just supply containers.

We build packaging stories that sell.

Ready to create the perfect glass packaging for your brand?

Connect with us:

● Email at sales@ajantabottle.com

● Phone/Whatsapp: +91 9891098918

You can also shop from more than 500+ packaging solutions on www.ajantabottle.com – India’s first ever comprehensive packaging e-commerce portal.

For additional information, browse through our blog at https://www.ajantabottle.com/blog/ or subscribe to our latest updates through our social media channels,

*YouTube channel: https://www.youtube.com/c/Ajantabottle

*LinkedIn Page: https://www.linkedin.com/company/ajantabottle

*Facebook Page: https://www.facebook.com/glassbottleindia

*Instagram Page: https://www.instagram.com/ajantabottle

*Google Business Profile Manager: https://g.page/r/CXTH9MKpe2DuEBM/review