When it comes to packaging, one challenge that is most underrated is making your glass bottle compatible with high-viscosity formulas without tampering with the quality of the products, consumer experience, or operating efficiency. Whether you are a food manufacturer packaging thick sauces, a cosmetic brand filling out high-quality serums, or a pharmaceutical company manufacturing syrups and suspensions, the improper selection of the glass bottle can lead to everything from ineffective filling of products to unsatisfied customers.

In the case of brands and business owners, it is not going to be an option but a direct measure in safeguarding your brand reputation, returns, and optimizing expenses that go on in the operation process. This guide takes a deep dive into what high-viscosity packaging requires of your glass bottle and how you can choose, test, and take care of the proper solution in order to get the results you need.

Understanding High-Viscosity Formulas in Packaging

The resistance of a fluid to flow is defined as viscosity. The thicker the more viscous the product and the lower the velocity at which it flows and the less the more viscous the product and the higher the velocity of the flow. This property affects packaging, storage, and dispensing of a product in significant ways.

Slow and sticky products, with high viscosity (e.g, honey, shampoo, ketchup), have to be packed in containers where they can be dispensed under control without clogging.

They are low viscosity products (e.g. water, milk, juice), thin and runny, and they should also be poured out of some packaging that is convenient and not spills.

- Food Beverage: Honey, syrups, molasses, thick sauce, smoothies

- Cosmetics: Creams, gels, serums, and oils

- Industrial Fluids – Lubricants, resin & specialty chemicals

The thicker the product, the more you should take care of the bottle design, compatibility of the closures, and the calibration of the filling process. High-viscosity products do not lend themselves to being processed as common liquids, and the risks are higher in terms of operational efficiency and customer experience levels.

Why Glass Bottles Are a Good Choice

For many businesses, a glass bottle is the preferred packaging for high-viscosity products. This is not just due to tradition but also because of technical and branding advantages.

Chemical Inertness

Most substances do not react with glass, and hence, this makes it the safest choice for storing the flavor, scent, texture, and quality of thick liquids. This is crucial in terms of food safety as well as high-value cosmetic formulation.

Premium Brand Perception

Premium goods: products of high viscosity are usually sold as premium products. Glass offers the visual transparency, heft, and haptic qualities conducive to supporting an image of luxury or high quality.

Sustainability Edge

Glass can be used indefinitely, which is a factor that can be used to attract environmentally friendly consumers. This is another sustainability advantage that can be used in marketing positioning to charge higher prices.

Superior Barrier Properties

Glass provides superior protection against oxygen and moisture intrusion, thus preventing viscous products from turning off earlier than many plastics.

To brands, these benefits do not involve only functionality, but competitive differentiation within a busy market.

The Main Characteristics of a Glass Bottle to Hold High-Viscosity Products

- Open Neck or Wide Mouth: Allows easy and fast filling and easy dispensing by customers by pouring or scooping the product.

2. Smooth, Non-Textured Interior: Avoids the sticking of thick products inside, minimizing wastage and hindering the circumstances of a container remaining half empty.

3. High-Strength, and Heat Resistant Glass: It can withstand hot-filling, vacuum sealing, and processing, and it does not crack or fail to maintain its structure.

4. Compatible, Airtight Closures: Comes in pairs with lug caps, screw caps, or pump dispensers to keep fresh, preserve taste and texture longer.

5. Stable, Wide-Based Design: It avoids spills when being used, a factor that is critical when scooping or pouring thick materials.

6. Product Visibility or Light Protection: Clear glass is used to show the quality, and amber/green glass protects light-sensitive products from UV damage.

7. Filling Line Compatibility: Designed for easy adaptation to automated or semi-automated filling machines for efficient production

8. Ergonomic Grip: The shape and size make the bottle comfortable to hold, despite the sticky or heavy contents in the bottle.

Design Considerations for Glass Bottles with High-Viscosity Formulas

Glass bottle design is important in product performance, fill efficiency and consumer satisfaction.

Neck Diameter

Larger necks enhance quicker filling and dispensing of the product. This is especially necessary where the product is supposed to be poured or scooped.

Shoulder Slope

A gentle slope inside the bottle allows viscous products to flow more easily, reducing residue and waste.

Internal Surface Finish

Internal finishes can allow the free flow of products to avoid sticking, particularly during times of final bottle use

Base Stability

Stability ensures that bottles do not fall over during filling or in use, which decreases accidents or slowdowns in operations.

These design specifications can significantly affect the behavior of your high-viscosity product through its production and consumption

Small Glass Bottles for High-Viscosity Products

The use of large jars is not unusual when it comes to thick products, but small glass bottles are gaining prominence in terms of premium packaging options.

Advantages of small glass bottles include:

- Ideal for high-value and concentrated products such as cosmetic serums or specialty oils

- Promote testing and gift offers

- Minimize waste for slower-use products

The most popular uses include mini-honey jars in food service, measured-dose pharmaceutical syrups, and deluxe skincare packs. Small beer glass bottles are also quite portable, along with their upscale images. This makes them an appealing option to those brand owners who wish to concentrate on high-end markets.

Material and Structural Strength

High-viscosity products require glass bottles with robust strength and durability.

Glass Type

Soda-lime glass is the most common, but for temperature fluctuations during processes such as hot-filling, borosilicate glass is better.

Wall Thickness

Thicker walls add durability but also weight. The balance should be struck between strength and shipping efficiency.

Annealing Quality

Well annealed glass contains less internal stress and therefore is less likely to break when filling, capping, or shipping.

A solid bottle safeguards your product and the image of your brand.

Compatibility with Closures

The most common mistake in packaging planning is the neglect of closures, despite the fact that, at least with high-viscosity formulas, the closure is nearly as critical to the product as the bottle itself.

Key closure requirements:

- Must seal tightly to prevent seepage, especially since thick liquids can move slowly but persistently toward gaps

- Should allow controlled dispensing without excessive force

The most popular types of closure are screw caps with liner, pump dispensers with gel or lotions, and wide-opening flip-top caps. Before mass production, closures must be tested with the actual product must be carried out under real-world conditions

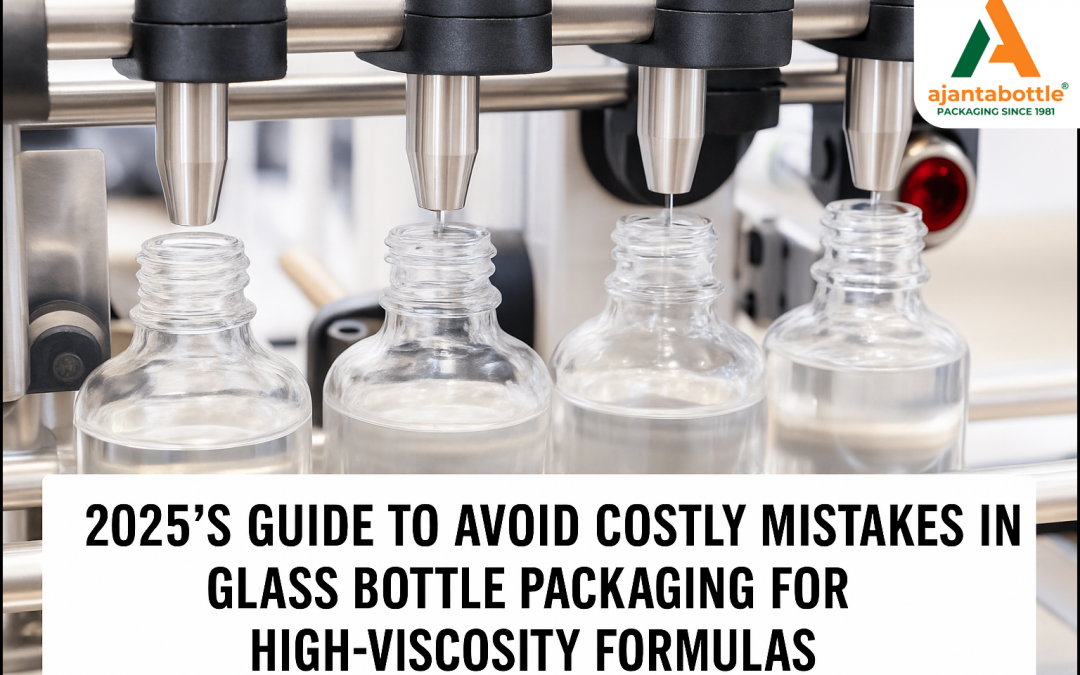

Filling and Production Line Adjustments

Thick liquids demand particular arrangements to be filled in a glass bottle to create precision, effectiveness, and safety of the product.

Filling Speed

The slow filling also helps avoid overflow and provides an opportunity to settle viscous products

Nozzle Size

Wider nozzles prevent plugs and improve flow.

Temperature Control

A viscous product can be slightly heated to reduce the resistance to flow, which makes it easier to fill, but should not be done in a manner that affects product integrity

Specialized Fillers

Viscous products can be filled by piston fillers or positive displacement pumps, rather than gravity fillers.

The right equipment can substantially improve the efficiency of production and reduce wastage.

Branding and Labeling Strategies

A high-viscosity product glass bottle is more than a container; it is part of your brand.

- Clear glass can showcase the richness and texture of the product

- Embossed branding can form a tactile premium feel

- High-end bottles can have silk-screen printing or metallic foil on small glass bottles

Label Durability

Viscous products are usually left behind on the outside surface of bottles, and therefore, the labels used have to be waterproof and smudge-free. Proper branding raises the value of the product in the minds of consumers and encourages loyalty

Testing Protocols Before Launch

Rigorous testing guarantees your glass bottle is commercial-ready.

Key tests include:

- Flow trials at various temperatures

- Drop and impact tests for transportation durability

- Leak testing for closure compatibility

- Stability tests on shelf-life of product and packaging integrity

Testing should simulate real storage, shipping, and usage conditions to prevent costly recalls or customer dissatisfaction.

Cost vs Value in Glass Bottle Selection

While specialized glass bottles for viscous products may come with higher upfront costs, they often provide a strong return on investment

Benefits include:

- Reduced product waste

- Fewer returns and complaints

- Improved consumer satisfaction

- Justification for premium pricing

Don’t look at packaging as just an expense, look at it as an investment in growth and customer retention for your brand.

Sustainability and Consumer Trends

Sustainability is no longer a niche feeling; it’s a mainstream one. Glass is a top performer in sustainable packaging, and consumers are opting for products in recyclable packaging.

Trends include:

- Refillable small glass bottles in cosmetics and food

- Deposit-refund systems to promote the recovery of packagings

- Upcycling projects that promote artistic reuse of bottles

Checklist for Business Owners

Before committing to a glass bottle for a high-viscosity product, ensure you have:

- Appropriate neck size for filling and dispensing

- Verified glass strength and durability

- Closure compatibility for sealing and dispensing needs

- Adjusted filling line processes

- Considered both large and small glass bottle formats

- Completed thorough product and packaging testing

Conclusion

The glass bottle is much more than a container to brands and business owners. It is a tactical aspect of product quality, operating efficiency, and customer satisfaction when dealing with formulas that have high viscosity. Businesses can maximize their brand promise through each drop of their products by paying attention to issues of design, structural integrity, compatibility of closure and efficiency of production.

Regardless of whether you opt to have bottles made of glass and in sizes exclusive product lines or larger format to make bulk sales, the important factor is to match up packaging decisions to the structural requirements as well as the market positioning. Your glass bottle can turn into a resource that will help your brand grow through the years with the proper planning and testing.

Ajanta Bottle: Packaging That Feels as Good as It Looks

At Ajanta Bottle, we believe every great fragrance deserves a bottle that captures its essence at first glance. With over four decades of packaging expertise, we help perfume brands turn their vision into packaging that speaks, sells, and stays memorable.

From color psychology consultation to premium decoration techniques such as gradient coating, frosting, UV printing, and embossing, we offer end-to-end solutions tailored to your scent, story, and strategy. Whether you’re creating a minimalist niche collection or launching a vibrant festive edition, our team will help you choose the right color palette, cap style, and finishing detail to ensure your product stands out—on the shelf and in the heart.

Your perfume is more than a product. It is a story, a memory, an emotion. Let us help you bottle that story beautifully.

Ready to create the perfect glass bottle packaging for your brand?

Connect with us:

● Email at sales@ajantabottle.com

● Phone/Whatsapp: +91 9891098918

You can also shop from more than 500+ packaging solutions on www.ajantabottle.com – India’s first ever comprehensive packaging e-commerce portal.

For additional information, browse through our blog at https://www.ajantabottle.com/blog/ or subscribe to our latest updates through our social media channels,

*YouTube channel: https://www.youtube.com/c/Ajantabottle

*LinkedIn Page: https://www.linkedin.com/company/ajantabottle

*Facebook Page: https://www.facebook.com/glassbottleindia

*Instagram Page: https://www.instagram.com/ajantabottle

*Google Business Profile Manager: https://g.page/r/CXTH9MKpe2DuEBM/review